Think multiple of 10. He chose 12vac for a reason

Announcement

Collapse

No announcement yet.

Motor Generators

Collapse

X

-

This comment has been taken out of context by you who is a unable to count. 100watt bulbs x 6 but in the end will be much more. Still you don't know what is being said here so it would be best if you sit and listen.Originally posted by pmgriphone View PostBromeyBoy,

Your 600W output statement is total nonsense (as usual).

The meters clearly read under 500watts and over 400watts. Are you scared bro...? Scared it's gonna work before the job is done? Are you shakin in your boots bro..?

Relax, hold your tongue from flapping and see how it's done. 95v X 4400ma =? I'll learn ya dern ya. Stop interrupting class. The answer is 418w you get a D-

This is not 60hz, this it 1100hz. Do you know the difference? No, you think it doesn't matter because you don\t know what you are talking aboutOriginally posted by pmgriphone View PostBromeyBoy, ..attention seeker that loves exaggeration.

96V over a 100W bulb ..consider the resistance .. to be 144ohms, output power is only 64W.

.

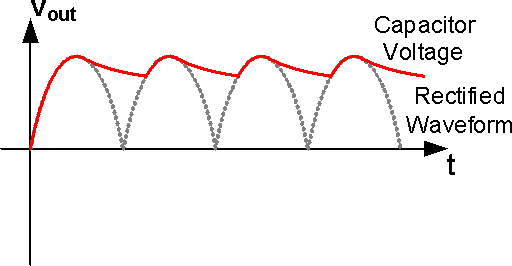

Do you see the common mistake? He has an improper rectifier circuit. A 124vac rectified should read 155vdc but you guys just talk, you have no idea what just happened. He has no caps

Last edited by BroMikey; 01-23-2022, 04:37 AM.

Leave a comment:

-

BromeyBoy, at this point you need to stop posting fake news and let Dave do his thing. Clearly the numbers you are stating are total nonsense, just like the stuff you post about anyone's videos. I think you are just an attention seeker that loves exaggeration.Originally posted by BroMikey View Post

Yes true the 1100hz needs a fast bridge and a smoothing cap to give great measurements. Light bulbs like dc. 96vac (guessing) is about 120vdc. Unless you get more output per coil it looks like 400watts input and 600watts output before neutralization

From Dave's video it is very clear that his input power is 5A at about 100V, or about 500W. And 96V over a 100W bulb output, so about 100W at best, but most likely if we consider the resistance of the 100W bulb to be 144ohms, output power is only 64W.

Your 600W output statement is total nonsense (as usual).

Leave a comment:

-

https://www.ebay.com/itm/19367920695...3ABFBMoNq5ytBf

Determine the output voltage of the secondary winding your transformer. This value, given in volts, is provided on the data sheet that accompanies the transformer. For this example, we will use 18 volts.

Subtract 1.4 volts from this value to determine the total output voltage of the bridge rectifier. In this example, that value is 18v - 1.4v = 16.6v.

Multiply this value by the frequency of the transformer's secondary winding. In most cases, this is 60 Hz. In this example, the value is 16.6 x 60 = 996.

Multiply the total current, expressed in amps, required by your load by 5. For example, if your circuit requires 5 amps, 5 x 5 amps = 25 amps.

Divide the value found in Step 4 by the frequency multiplied by the output voltage. In this example, the equation looks like this: 25 amps / 996 = .0251

Express this value in micro-farards by multiplying the value in Step 5 by 10^6. The final value for this example is 25,100 microfarads. This is the rating required of your capacitor.

This one example, not your numbers but you can see 60hz and 1100hz are two different animals. For 60hz you need 3 or those caps but 1100hz take far more. Do the math.

Last edited by BroMikey; 01-23-2022, 02:03 AM.

Leave a comment:

-

Yes true the 1100hz needs a fast bridge and a smoothing cap to give great measurements. Light bulbs like dc. 96vac (guessing) is about 120vdc. Unless you get more output per coil it looks like 400watts input and 600watts output before neutralizationOriginally posted by Turion View PostOutput across the AC load is 96 volts AC.

the AC meter I am using may not give a correct reading .

I guess you can not see down into the rotor gap to know if it is a big space?

Caps give a straight line and rectifiers make a pulsating waveform. You want the peak power

Last edited by BroMikey; 01-23-2022, 01:40 AM.

Last edited by BroMikey; 01-23-2022, 01:40 AM.

Leave a comment:

-

Output across the AC load is 96 volts AC. Going to put in a 2 or 3 amp meter, and then go down to a 1 amp meter if it looks like it is below 1 amp output.

Voltage unloaded was definitely 260 volts on the old machine ( got a text a few minutes ago confirming that's what they recorded) so it should be higher. I will figure it out eventually. Of course the AC meter I am using may not give a correct reading at the frequency we are running at here with 24 magnets at 2800 rpm.

Leave a comment:

-

Nice progress. So you will have more output than ever before when you get the cores closer than 3/16" GapOriginally posted by Turion View PostCan’t tell if coils are all the way in or not, but I don’t think so. I think they are out about 1/8 still. Will keep working on it. Here’s what I am getting now.

https://youtu.be/S4ClaC_nsaY

Did you say that meter reads 96vdc or 96vac?

Leave a comment:

-

Can’t tell if coils are all the way in or not, but I don’t think so. I think they are out about 1/8 still. Will keep working on it. Here’s what I am getting now.

https://youtu.be/S4ClaC_nsaY

Leave a comment:

-

keep me laughing, the guy throwing dirt was freaking out, probably feels like a dope now.

No power steering shows how old you are. I didn't play football in high school because I was tall and skinny and did not want you stocky guys breaking me in half. A few tough dudes took out knees and warned me not to join. We played in the hood. Also hockey, just drop a garden hose 24hrs and boom, instant rink. It stayed 10-minus 20 in Michigan

Good to know the details about your black box. It will be everything you wanted 17 and counting

17 and counting

Leave a comment:

-

That's why each coil has to have the core face ground off flat with the face of the coil holder. These two coil holder plates holding the coils back (one on each side of the rotor) are held apart by four precision spacers at the four corners, and the rotor is precision centered between them with spacers made by the machinist. This is why, when it wasn't right, I couldn't just jump on it and get it done. PLUS, the wobble I was seeing was definitely in the shaft, which was bent in shipping to me. So it wasn't all my imagination. We had a new shaft made with the plate on it that the rotor bolts to.

Got the hand taken care of. Now just have to wait for it to heal. My splint comes off to take showers, so that's nice. Always had to have the plaster cast before. Can't tell you the number of times I have broken things in car wrecks and football games in my life, so kinda used to having a hand in a cast. Had a break in my wrist in high school that they ended up rebreaking twice and putting two pins in to get it right, and I was in casts for well over a year. That was the end of football for me. Had to drive back and forth between Yuma where I lived and Phoenix AZ to see a specialist at least every two weeks, and it was like a six hour round trip. That got old quick, and I was a KID, not an old goat like I am now. Didn't have power steering, so one-handing it all the way built up muscles. And it was a four speed, so shifting was an adventure. At least NOW I have power steering and an automatic. Too easy.

0.jpeg

Hope to finish up the coils today and at least get production numbers from one coil pair so I have an idea of total machine output. But this is real life, and every day is an adventure. The guy next door to me was burning big piles of leaves yesterday, and let them burn out. But during the night we had incredible heavy winds come up that fanned the embers, and I have video footage of him at two in the morning out there digging dirt, throwing it on the flames, and trying to put out fires with the wind blowing embers everywhere, mostly right into the trees across the street. He could have burned down the whole neighborhood in the middle of the night. You never know what the day will bring.Attached Files

Leave a comment:

-

I'll bet your high karate feel's bad 3 days runnin? I just did 5 days running so I can feel ya bro..... I have been stuck in one position in a car all week with a 4-6 hr range per day drive time plus Dr. calls.

3 days runnin? I just did 5 days running so I can feel ya bro..... I have been stuck in one position in a car all week with a 4-6 hr range per day drive time plus Dr. calls.

Take your time an enjoy this most critical part of the build. It took me forever to gap my rotors. I know yours cannot be adjusted like mine. Then I got to thinking. What if Dave had a 2,000ths plastic shim to go in front of his coils? That way if one gap needed to be adjusted, you could take a shim out or put one in.

It is critical that each gap be the same as the next one or a push pull effect will cause the rotor to jitter. Last edited by BroMikey; 01-22-2022, 08:29 AM.

Last edited by BroMikey; 01-22-2022, 08:29 AM.

Leave a comment:

-

Got it. I was confused by the phrase "rotor DO 40,000ths". How do yo "do" a gap. Now I understand what you meant. I thought maybe you meant 40,000rpm and the "ths" was some kind of typo. I have no idea what the current gap is. Haven't measured it.

I doubt you can EVER get the kind of precision you want out of plastic rotors. But again, this is only a PROTOTYPE to prove concept, NOT a production model. Possibly an aluminum or steel rotor ENCASED in plastic thick enough to eliminate the eddy currents or the attraction of the magnets to steel would be the optimal rotor for this type of machine. I'll leave that to the next generation of folks. I just want to prove it works.

I have had an extremely busy morning and have not gotten downstairs to file on the cores yet. Hopefully I can do that. Since I traveled to Sacramento 3 different times this week for different things, all related to breaking my hand, I am way behind on things at home and have been catching up. But tomorrow is Saturday and if I haven't gotten this done by the end of the day tomorrow, the guys will come on Sunday and help me out. So one way or another it will get done. So getting back to work now or it will NEVER get done.

Leave a comment:

-

Gap? 60,000ths is what I thought your target gap is. Less gap drives up the power output but it would grindOriginally posted by Turion View PostI have no idea what 40,000ths means.

20,000ths- 40,000ths is a standard minimum for motors and generators

https://www.youtube.com/watch?v=eVIw8ERZsFwLast edited by BroMikey; 01-21-2022, 10:59 PM.

Leave a comment:

Leave a comment: