In this diagram , I will explain how the Lenz Law causes 2 brakes and thus decreases the RPM of the Magnet Rotor, when the Conventional Generator coil is connected to the Load.

When the N pole Rotor Magnet glued to the Rotor approaches the Coil Core , the Coil is very quickly magnetized , before the Rotor Magnet reaches the Top Dead Centre ( hereafter mentioned as TDC) . So then the Coil Core will also become a N pole magnet which resists and repels the rotor magnet which is also the N pole magnet and still approaching the coil core. . So this is the First break of the Lenz Law. It is caused by Magnet Repulsion.

Then when the Rotor Magnet passes the Coil Core , the Coil is demagnetized and reverses the current induced in it, so then the coil core become a “ S” pole Magnet and it attracts the passing “N” pole magnet of the Magnet Rotor . So this is the second break of the Lenz Law. This is how the Lenz Law decreases the Rotor RPM when the Generator coil is connected to the Load.

So now I am going to explain you, how the Lenz law becomes much delayed and how the Rotor RPM increases when we use the Special Regenerative Acceleration Coil ( hereafter mentioned as Regenx Coil ).

In this Regenerative Acceleration Effect there are two Parameters .

- The Coil should have many turns of copper wire and it should be high impedance , high resistance coil.

- The Rotor RPM should be high .

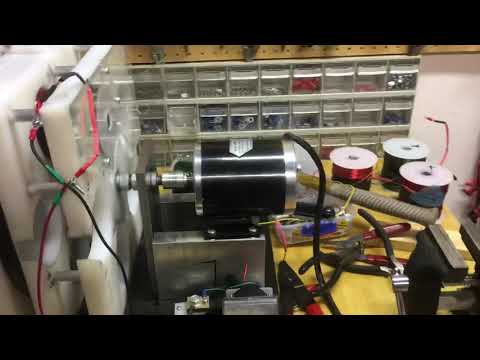

The following is the Coil I made which has over 8000 turns of Guage 28 copper wire and it is about 600 Grams in weight.

You can not sucker other people while I am here. Connections get crossed up or fail, there are many.

You can not sucker other people while I am here. Connections get crossed up or fail, there are many.

Leave a comment: