altrez,

It IS simple. That is what I don't think people really understand. We HAVE all the pieces. We just need to put them all together. If you look at the threads I have TRIED to start on this forum, this thread, the "3BGS" thread, and the "All About Your Basic Coil" thread have all been devoted to one purpose...talking about the basic, simple components that can be assembled to put together a machine that works. The "All About Your Basic Coil" thread was to talk about the "Energizer" portion of this basic setup. If we want to produce electricity IN VOLUME we need to add an energizer to the mix, and use the motor to run it.

That energizer needs to have some very specific parameters. It needs to produce as MUCH power as possible, or a SPECIFIC amount of power based on its application and it needs to be "low drag". We have heard this term before, but I want to be more specific about it.

1. It needs to as be Lenz free as possible, which means producing as little back EMF as it can be engineered to produce, and engineered to produce it when it hurts us the LEAST. You may not be able to eliminate it, but engineer around it if you can.

2. It needs to have as LITTLE magnetic attraction between the core material and the rotor magnets as possible, and if you can, control WHEN that happens (with electromagnets you have SOME control)

And then there is the Thaine Heinz Effect, or the so called speeding up under load. I have seen this Many, MANY, MANY times. I have a video of My generator doing it with just two coils...one running as a generator coil, and the other shorted out to speed it up under load. But to show that video here, I would have to show my generator, which I am not ready to do yet, because it is not finished. Here is a video of someone ELSE doing the same thing:

https://www.youtube.com/watch?v=fJl0TO_aR6M

On my generator I do NOT have The Leedskalnin U shaped coil cores, nor do I have the two coils connected together in series as in this video, so there are other configurations that will accomplish the same thing. And realize this will ONLY work with resistive loads, NOT inductive loads.

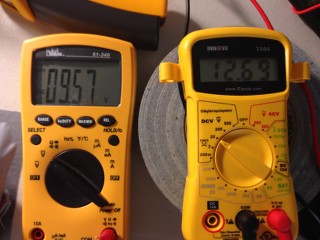

You don't build a coil that meets the parameters I have talked about here the first time out of the gate. (Unless you have the luck of the Irish) You build it by experimenting and experimenting and experimenting. You try different sizes of wire, different lengths of wire, different wrapping and twisting patterns, different coil cores. I have built hundreds of coils. I can show you pictures if you don't believe me. I have shelves full of them. I have a huge box full of copper wire from discarded coils. I have a coil that appears to be working for me, but I have ideas on how to improve it. I have built a unit to do NOTHING but test the output of coils, so I can turn a rotor by running a motor at a specific rpm with a known voltage and amperage, and see how a particular coil affects the RPM, the amp draw of the motor (kinda the same thing) and how much voltage and amperage it will put out to a known load.

I have been working with some core materials lately that are flat amazing. I have gotten free samples from a company, and they are providing me with enough of the material to rebuild my prototype. This will also give me that opportunity, as much as I hate winding coils, to rewind my coils in a more efficient configuration.

I wanted to get a BUNCH of people involved in this testing process because it is as expensive as heck, and I don't have the TIME to do everything. Right now I am incredibly busy, but by the first of the year I will be in a position where working on this stuff will once again be my full time job.

In my opinion, it is not enough to have something that "works." If I am going to put something out there for people to build, I want it to be bullet proof. I want it to be so simple that if it is done CLOSE to the way we say to do it you will get the results we say you will get.

Like I said at the very beginning of this thread.

The BEST, most efficient motor we can find

The BEST energizer we can build

A flywheel

Some batteries to power it up

A control circuit.

Run it on the 3BGS setup

Look at post #3312 On "The 3 Battery Generating System" Thread

I made that post on July 21, 2014.

I talked about uses for the 3BGS and I talked about EXACTLY the same thing.

WHY you ask?

Because I have Matt's pulse Motor running an Energizer I spent a couple thousand dollars to design and build. I have a flywheel on it. I can run it in the 3BGS setup. I can MEASURE inputs and outputs. (And these are outputs to known loads where I measure the voltage and amperage) I can see how long the batteries last. I can see how much power I get out of the system. I have been working with this generator for well over a YEAR now. I can do the math.

To paraphrase what they used to say on the old Six Million Dollar Man show

"We have the technology. We can build it"

It IS simple. That is what I don't think people really understand. We HAVE all the pieces. We just need to put them all together. If you look at the threads I have TRIED to start on this forum, this thread, the "3BGS" thread, and the "All About Your Basic Coil" thread have all been devoted to one purpose...talking about the basic, simple components that can be assembled to put together a machine that works. The "All About Your Basic Coil" thread was to talk about the "Energizer" portion of this basic setup. If we want to produce electricity IN VOLUME we need to add an energizer to the mix, and use the motor to run it.

That energizer needs to have some very specific parameters. It needs to produce as MUCH power as possible, or a SPECIFIC amount of power based on its application and it needs to be "low drag". We have heard this term before, but I want to be more specific about it.

1. It needs to as be Lenz free as possible, which means producing as little back EMF as it can be engineered to produce, and engineered to produce it when it hurts us the LEAST. You may not be able to eliminate it, but engineer around it if you can.

2. It needs to have as LITTLE magnetic attraction between the core material and the rotor magnets as possible, and if you can, control WHEN that happens (with electromagnets you have SOME control)

And then there is the Thaine Heinz Effect, or the so called speeding up under load. I have seen this Many, MANY, MANY times. I have a video of My generator doing it with just two coils...one running as a generator coil, and the other shorted out to speed it up under load. But to show that video here, I would have to show my generator, which I am not ready to do yet, because it is not finished. Here is a video of someone ELSE doing the same thing:

https://www.youtube.com/watch?v=fJl0TO_aR6M

On my generator I do NOT have The Leedskalnin U shaped coil cores, nor do I have the two coils connected together in series as in this video, so there are other configurations that will accomplish the same thing. And realize this will ONLY work with resistive loads, NOT inductive loads.

You don't build a coil that meets the parameters I have talked about here the first time out of the gate. (Unless you have the luck of the Irish) You build it by experimenting and experimenting and experimenting. You try different sizes of wire, different lengths of wire, different wrapping and twisting patterns, different coil cores. I have built hundreds of coils. I can show you pictures if you don't believe me. I have shelves full of them. I have a huge box full of copper wire from discarded coils. I have a coil that appears to be working for me, but I have ideas on how to improve it. I have built a unit to do NOTHING but test the output of coils, so I can turn a rotor by running a motor at a specific rpm with a known voltage and amperage, and see how a particular coil affects the RPM, the amp draw of the motor (kinda the same thing) and how much voltage and amperage it will put out to a known load.

I have been working with some core materials lately that are flat amazing. I have gotten free samples from a company, and they are providing me with enough of the material to rebuild my prototype. This will also give me that opportunity, as much as I hate winding coils, to rewind my coils in a more efficient configuration.

I wanted to get a BUNCH of people involved in this testing process because it is as expensive as heck, and I don't have the TIME to do everything. Right now I am incredibly busy, but by the first of the year I will be in a position where working on this stuff will once again be my full time job.

In my opinion, it is not enough to have something that "works." If I am going to put something out there for people to build, I want it to be bullet proof. I want it to be so simple that if it is done CLOSE to the way we say to do it you will get the results we say you will get.

Like I said at the very beginning of this thread.

The BEST, most efficient motor we can find

The BEST energizer we can build

A flywheel

Some batteries to power it up

A control circuit.

Run it on the 3BGS setup

Look at post #3312 On "The 3 Battery Generating System" Thread

I made that post on July 21, 2014.

I talked about uses for the 3BGS and I talked about EXACTLY the same thing.

WHY you ask?

Because I have Matt's pulse Motor running an Energizer I spent a couple thousand dollars to design and build. I have a flywheel on it. I can run it in the 3BGS setup. I can MEASURE inputs and outputs. (And these are outputs to known loads where I measure the voltage and amperage) I can see how long the batteries last. I can see how much power I get out of the system. I have been working with this generator for well over a YEAR now. I can do the math.

To paraphrase what they used to say on the old Six Million Dollar Man show

"We have the technology. We can build it"

Comment