Hi UFO,

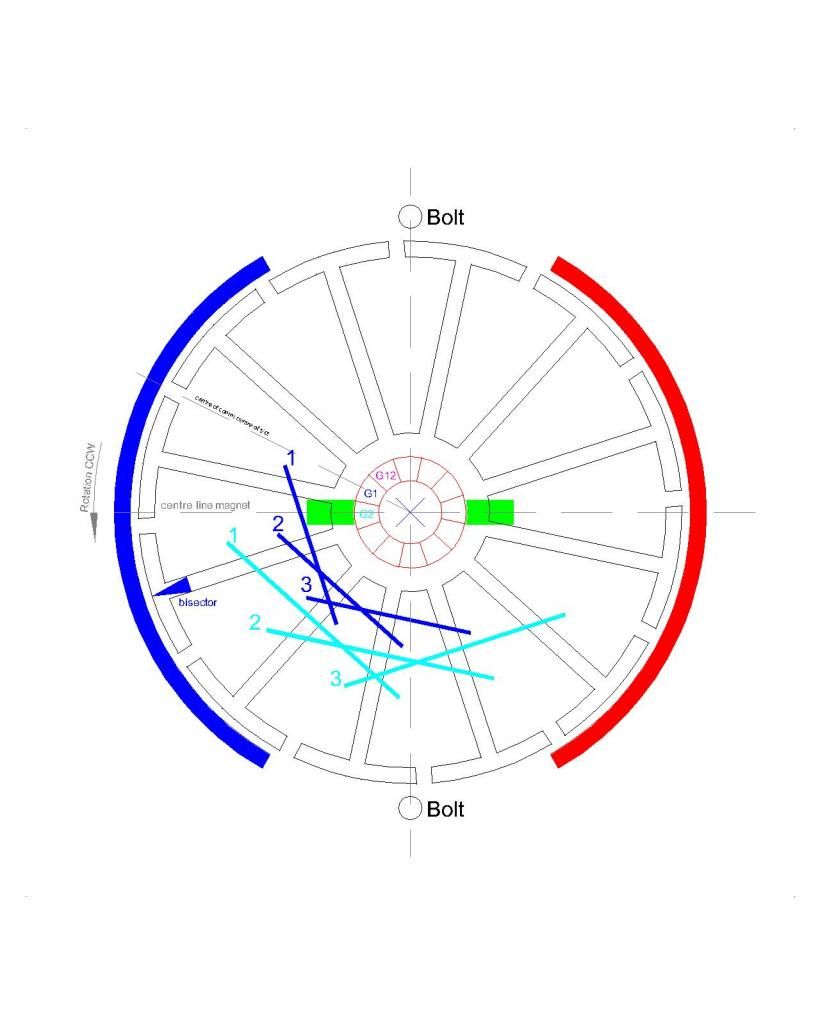

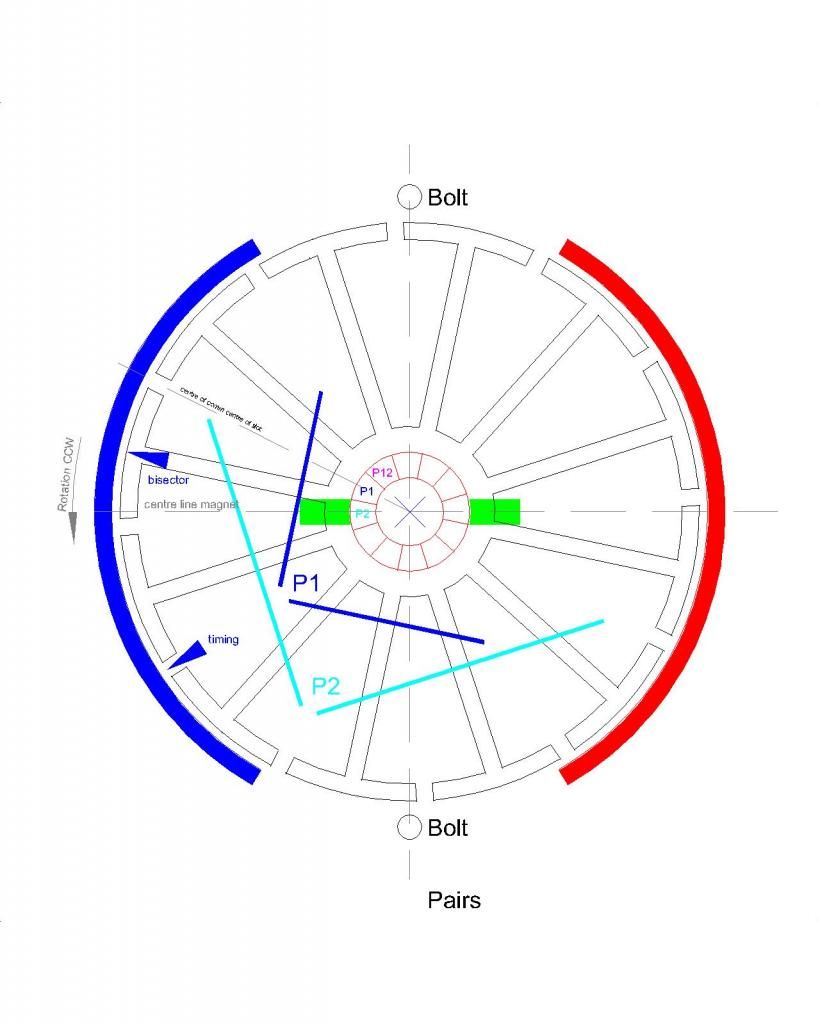

Been admiring your work but am not much of an electrician. Is there anyone in S. Florida that winds motors asymmetrically? I have an 8K watt generator that I would like to convert to your specs - nice to be ready for next hurricane season.

Love your work,

Paul

Been admiring your work but am not much of an electrician. Is there anyone in S. Florida that winds motors asymmetrically? I have an 8K watt generator that I would like to convert to your specs - nice to be ready for next hurricane season.

Love your work,

Paul

but maybe I should . . .

but maybe I should . . .

Comment