Originally posted by john_g

View Post

Well I wound it like Peter Lindemann says earlier in this thread only I spaced the second set of commutator brushes slightly less than 1 commutator segment as per a suggestion that he said would be okay. I've never wound a motor before but it does spin a bit with torque, the problem I'm having is that it just blocks itself when it goes around a half turn, it seems when the commutator segments with the wire ends touch the power on the half turn:

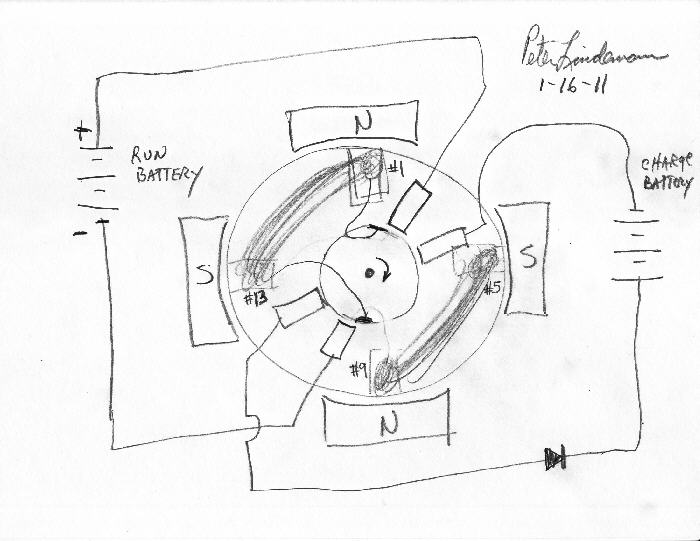

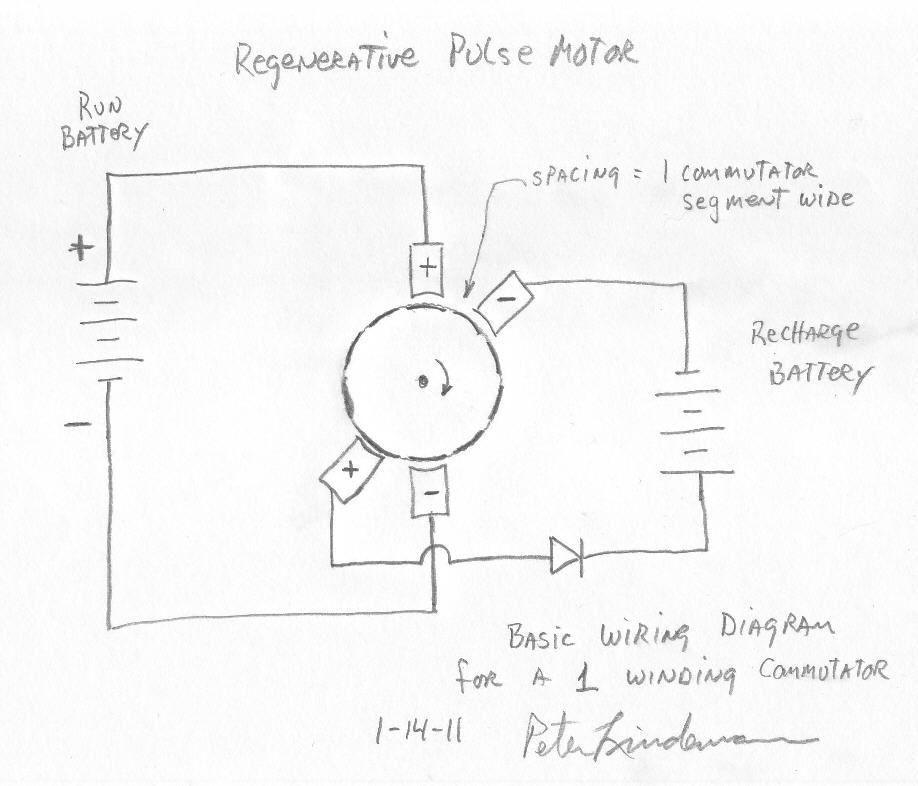

"Starting at the commutator side, lay your wire into slot #1. Coming out of Slot #1, lay the wire along the back edge of the rotor until you get to slot #5. Then enter slot #5 and come back to the commutator side again. Then go over to slot #9 and lay the wire down slot #9 and come out on the back side again. Then go over to slot #13 and come back over to the commutator side. Then, on to slot #1 again.... around in that pattern until the slots are filled. This is for a 16 slot rotor. The ends of the wires will terminate on two commutator segments that are 180* away from each other when the wire in the slots are sitting in the middle of the stator poles.Hopefully, you and everyone else can understand this. The commutator section is just arriving at the brush when the windings are in the middle of the magnetic fields. The windings on the back side of the rotor cross from #1 to #5 and from #9 to #13, assuming a 16 slot rotor.

I hope this clears this up, once and for all.

Peter"

Thanks!

Mike

Leave a comment: