I had thought about using aluminum before. However it would have to be THICK so it wouldn't bend. But previously when I would bend thicker aluminum it would crack at the seem. I have thought about heating it at the bending point but never had a chance to try. Perhaps this would be a good a time as any to try.

Thanks

Bizzy

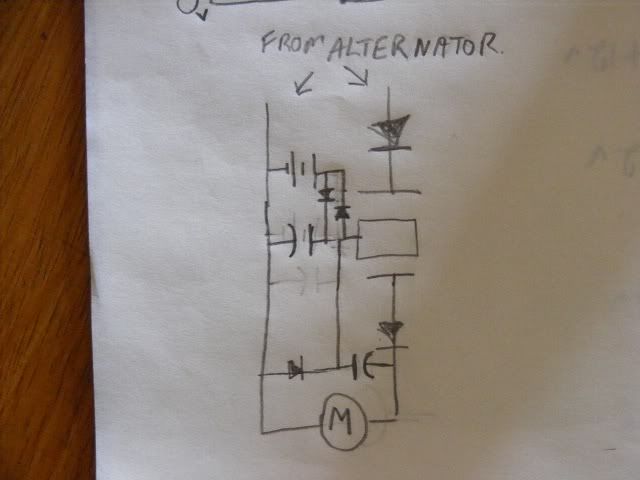

It would be better if the cap didn't go below the battery voltage, but

It would be better if the cap didn't go below the battery voltage, but

Leave a comment: