Hi bromikey, soulless apocalypse nightmare is more accurate and I can't wait for the unveiling.

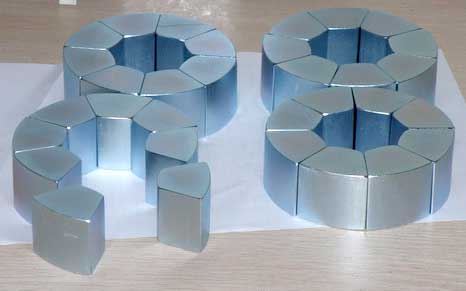

I'll probably go with the medium size device with many magnets.

And I think I will start building the rotor first and pick a motor, because I want to test this 12 strand 24awg. coil, that has 110 feet per strand, just to see how that does.

If it does nothing at reasonable rpm's, then I work on new coils.

Thanks turion, for the information.

peace love light

I'll probably go with the medium size device with many magnets.

And I think I will start building the rotor first and pick a motor, because I want to test this 12 strand 24awg. coil, that has 110 feet per strand, just to see how that does.

If it does nothing at reasonable rpm's, then I work on new coils.

Thanks turion, for the information.

peace love light

Comment