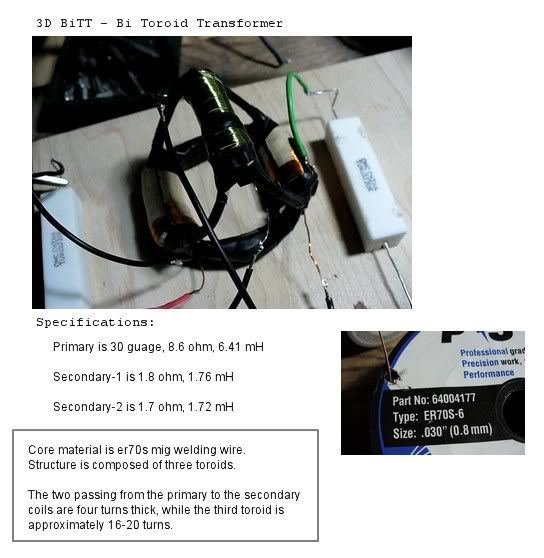

3D BiTT

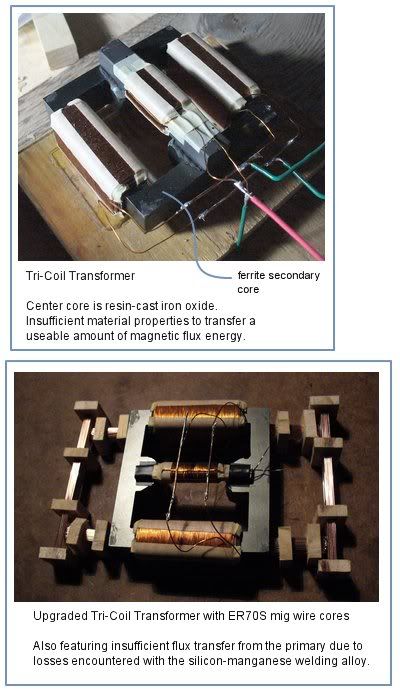

In going with the designs posted from Feb. 13th, the new

transformer is up and running. Shown as follows, it is

constructed with silicon - manganese steel alloy.

[ Performance Video ]

In going with the designs posted from Feb. 13th, the new

transformer is up and running. Shown as follows, it is

constructed with silicon - manganese steel alloy.

[ Performance Video ]

Comment