Hello everybody! (Note: Now new and improved Separator Cell design more efficient, durable and gas stable - click to jump to newer images and video)

As i operate my life according to a principle of maximizing my time and energy spent toward the pursuit of new energy solutions, I do very often flounder and stumble. My direction becomes skewed and varied on many tangents and so often my projects do not produce any measure of functionality. Well not this time.

I have to give great credit to Reg and Peter at HHO Fuel Cells & Accessories for their great separator cell design. It works. Currently they are reluctant to do international sales and are based out of Australia. Their website is a wealth of info and you might be able to work something out. I can make no promises as far as if they can help out on international orders.

My video of my Hydrogen - Oxygen Separator Cell build from HHO-research.com.au

And a few pictures

The finished Cell. Note the heavy connections. I would not recommend using air hose quick connectors as i have in this image. You can see impure elements in the steel that are oxidizing and causing rust on the ends. I will be swapping out for plastic 3/8" threaded fittings in the near future. They caused some yellow staining on the outlet tubes.

My rig. I've got a 2 bubbler (hydrogen in blue on the right and oxygen in 4" PVC on the left) and a main electrolyte holding tank (middle). The 2 power components on the left are a new lab 0-20volt, 0-20amp DC power supply i purchased from Ebay. and on top of it is the 0-30amp PWM which i purchased from HHO Fuel Cells & Accessories (works great and runs nice and cool). In the video i mention that the display is out of tune with actual amperage. Reg from hho-research.com.au advised that there is a tun-able adjustment Pot inside that i will regulate. In the video i am running at 10amps and 16volts at the power supply, standing voltage on the cell was about 12volts. I can push it up to about 16amps @ 20volts with the current amount of KOH - potassium hydroxide (I'm guessing i can do better). Edit - HA! LOL. HYDOGEN??? Crap I knew something didn't look right there. :P Oh well... too late now. I better go burn in a correction.

The tank system allows for the oxygen to bubble out through 4" PVC tank and loop back out and into the main tank (to collect overflow electrolyte). I'm still trying to sort out the physics involved, but being only 1 part Oxygen moving congruently to the 2 parts of hydrogen seems to draw an equal part of H2O along inline with the oxygen flow.

The flame. Quite small at this wattage but bigger than it appears for the most part. Nearly invisible to the eye, hydrogen shows up much better when using a catalyst to make its presence known. The camera, in this photo, actually picks it up better than my eye can. Being exclusively hydrogen offers a lot of benefits for both safety and usefulness. The applications for ambient heating, efficient usage in a combustion motor without having to adjust for advanced timing issues, or adjusting map sensors. The oxygen can literally undo the gains produced in burning straight HHO in a combustion motor. I'm going to be making another video on the different uses of the hydrogen gas flame.

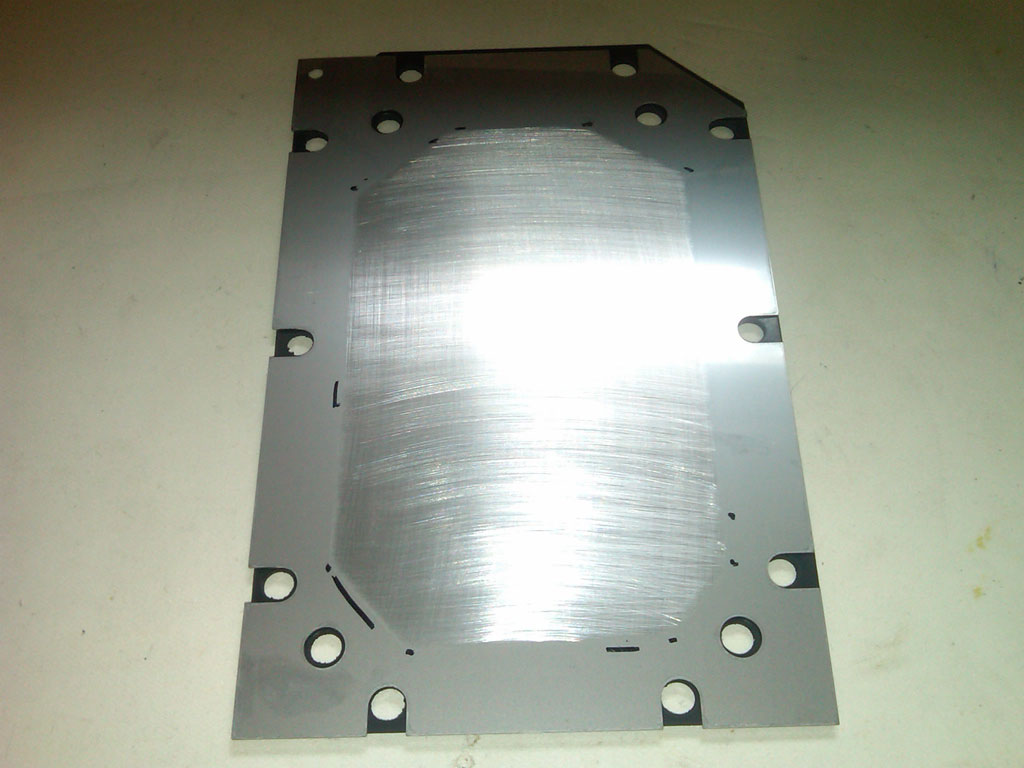

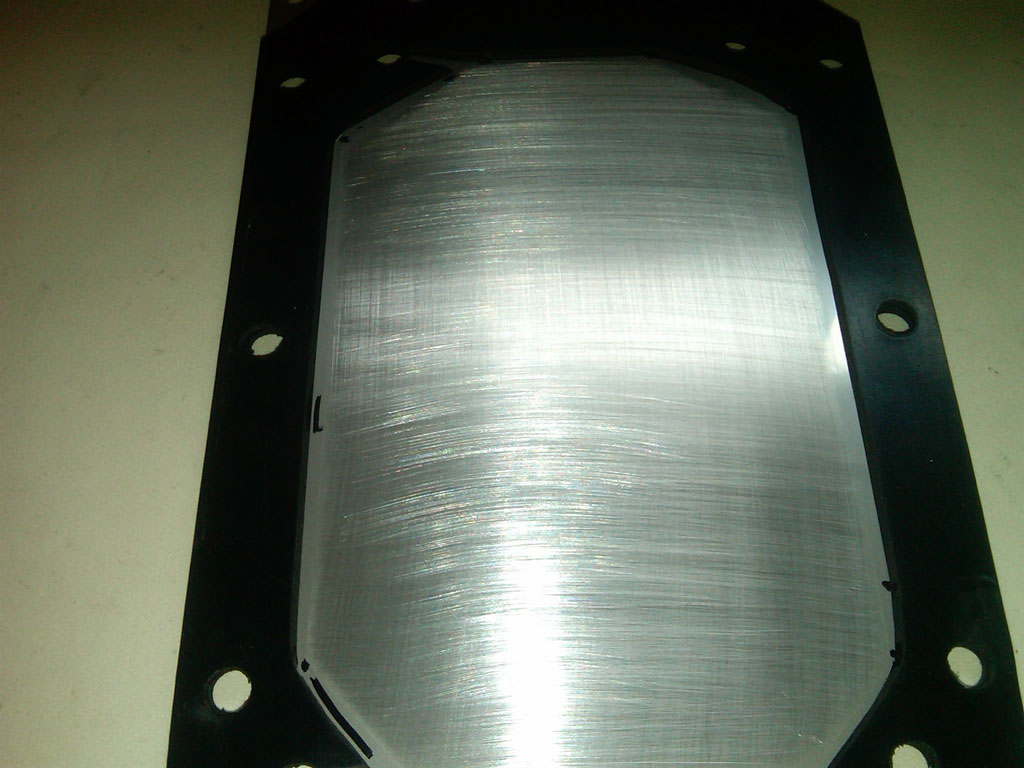

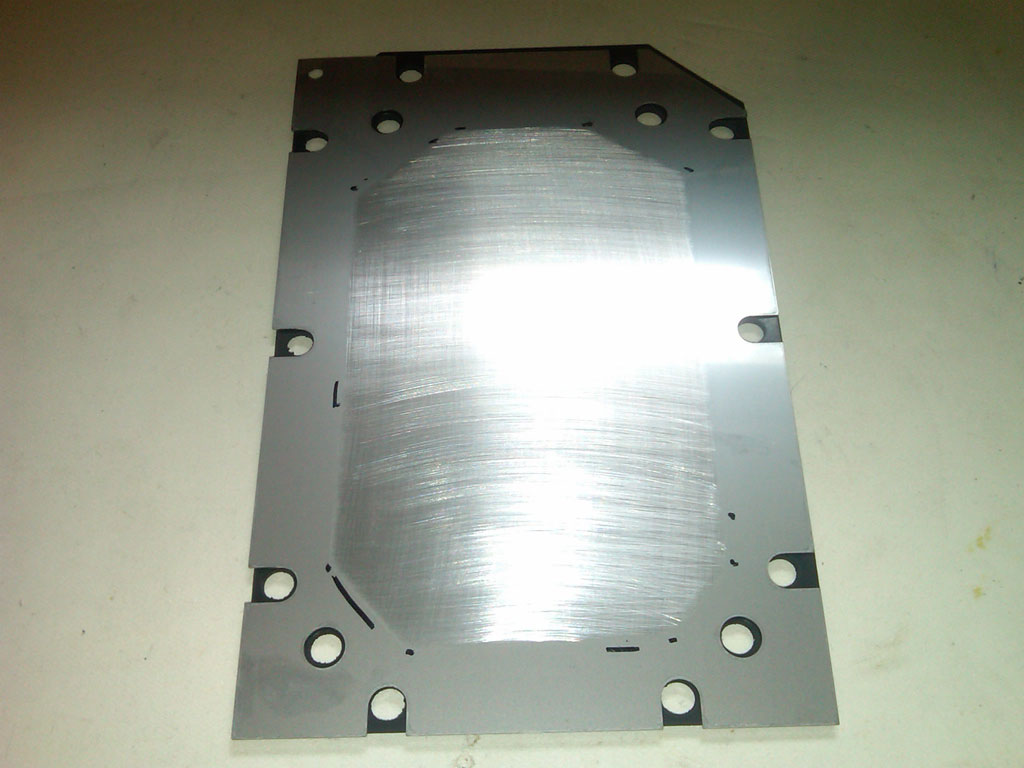

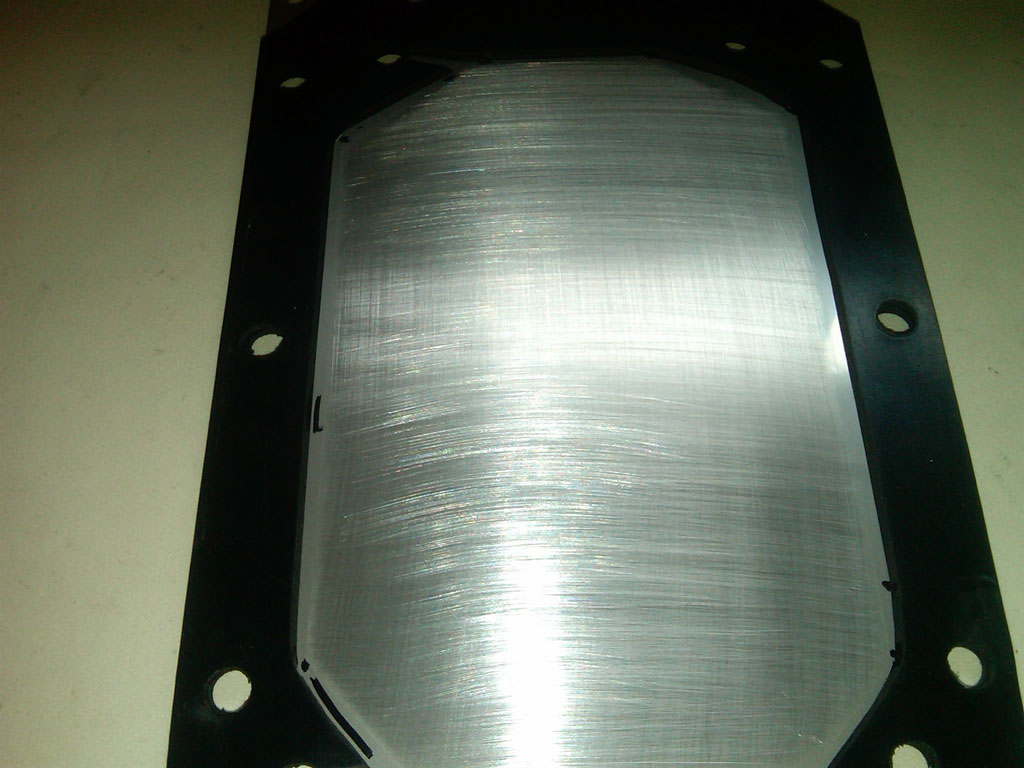

Here is one of the Active (+) stainless plates. These are laser precision cut by hho-research.com.au . Unless you hire them to build your cell, you will need to either sand blast or use 60 grit wet/dry sand paper (as i did) to score and increase the surface exposure of the stainless sheet.

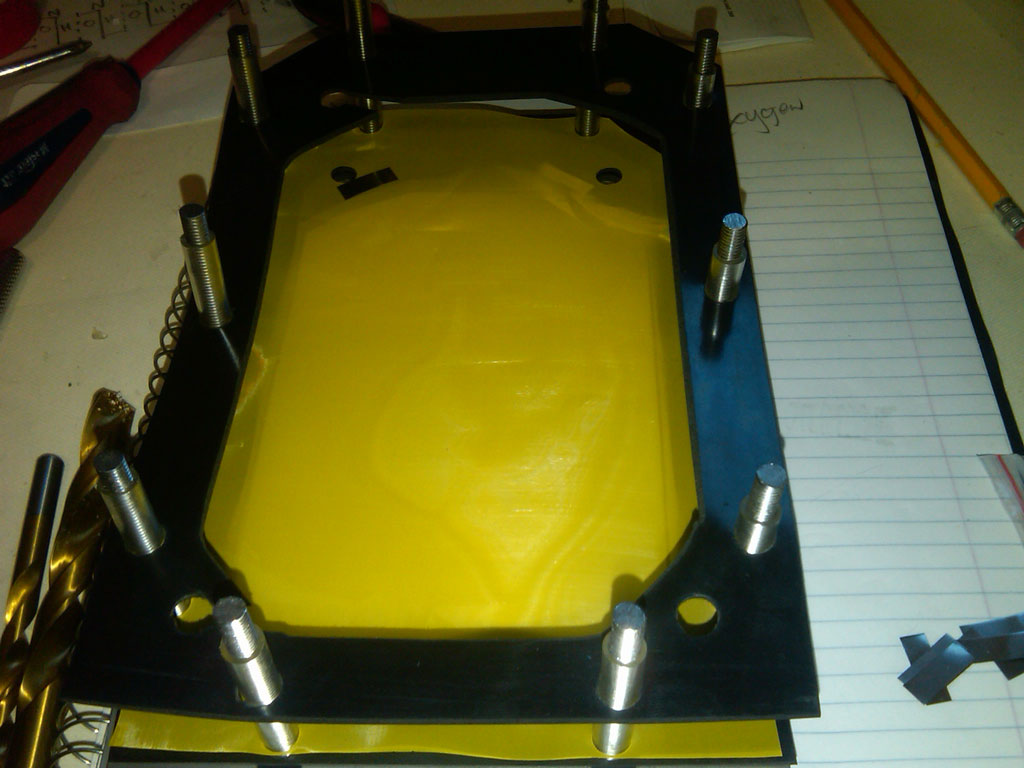

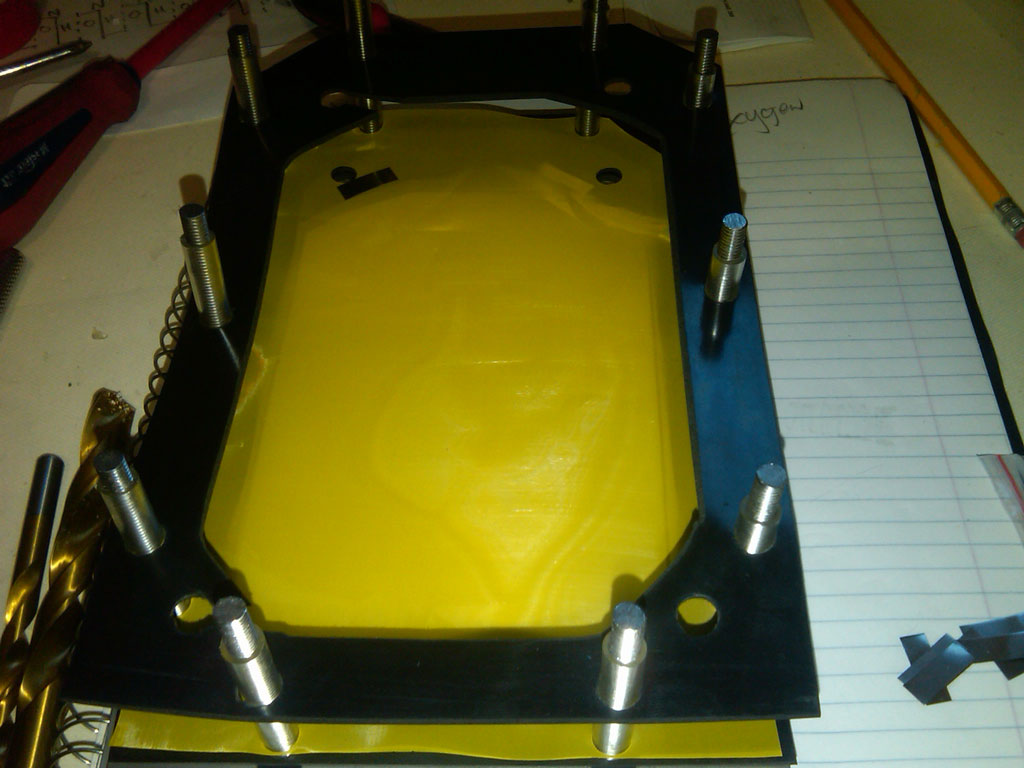

Here is a shot of one of the press-cut gaskets from hho-research. Note there is a small channel at the top leading to one side or the other, allowing you to direct the gases to one or the other side.

Then a laser cut membrane goes in between yet another gasket and then the next stainless sheet. Shims are used to keep the membranes from falling into the adjacent gasket channels on each side appropriately.

Knowing that neg produces hydrogen and pos produces oxygen, you can build your cell to separate the gas so one channel at the top will receive only hydrogen and the other will receive only oxygen. The end plates come as a un-drilled, un-tapped sheet of acrylic (i think). I think they don't recomment poly-carbonate as they will bust. I'll double check this. I do know that this build is not possible without a drill press and a tap set, unless you have hho-research build your cell for you at an additional cost.

The next step will be incorporating my new 6600 watt electric generator with a GEET reactor and vapour generator. I'm going to add the produced hydrogen to the fuel mixture and attempt to close the loop on the system by driving the electronics with the electric generator. We'll see how that goes. I'm well on my way and i'm going to see it through win or lose. The worst i can end up with is a really efficient electric generator. Maybe combine a small input to the system from a solar panel and i can put it over the top, so to speak. I already have 300watts of 6"x6" triple bus bar solar cells and will be assembling that panel soon too.

The costs are starting to mount up, but it sure is rewarding.

Thanks for watching and reading. I'll be back.

I'll be back.

L&L

TheDude

As i operate my life according to a principle of maximizing my time and energy spent toward the pursuit of new energy solutions, I do very often flounder and stumble. My direction becomes skewed and varied on many tangents and so often my projects do not produce any measure of functionality. Well not this time.

I have to give great credit to Reg and Peter at HHO Fuel Cells & Accessories for their great separator cell design. It works. Currently they are reluctant to do international sales and are based out of Australia. Their website is a wealth of info and you might be able to work something out. I can make no promises as far as if they can help out on international orders.

My video of my Hydrogen - Oxygen Separator Cell build from HHO-research.com.au

And a few pictures

The finished Cell. Note the heavy connections. I would not recommend using air hose quick connectors as i have in this image. You can see impure elements in the steel that are oxidizing and causing rust on the ends. I will be swapping out for plastic 3/8" threaded fittings in the near future. They caused some yellow staining on the outlet tubes.

My rig. I've got a 2 bubbler (hydrogen in blue on the right and oxygen in 4" PVC on the left) and a main electrolyte holding tank (middle). The 2 power components on the left are a new lab 0-20volt, 0-20amp DC power supply i purchased from Ebay. and on top of it is the 0-30amp PWM which i purchased from HHO Fuel Cells & Accessories (works great and runs nice and cool). In the video i mention that the display is out of tune with actual amperage. Reg from hho-research.com.au advised that there is a tun-able adjustment Pot inside that i will regulate. In the video i am running at 10amps and 16volts at the power supply, standing voltage on the cell was about 12volts. I can push it up to about 16amps @ 20volts with the current amount of KOH - potassium hydroxide (I'm guessing i can do better). Edit - HA! LOL. HYDOGEN??? Crap I knew something didn't look right there. :P Oh well... too late now. I better go burn in a correction.

The tank system allows for the oxygen to bubble out through 4" PVC tank and loop back out and into the main tank (to collect overflow electrolyte). I'm still trying to sort out the physics involved, but being only 1 part Oxygen moving congruently to the 2 parts of hydrogen seems to draw an equal part of H2O along inline with the oxygen flow.

The flame. Quite small at this wattage but bigger than it appears for the most part. Nearly invisible to the eye, hydrogen shows up much better when using a catalyst to make its presence known. The camera, in this photo, actually picks it up better than my eye can. Being exclusively hydrogen offers a lot of benefits for both safety and usefulness. The applications for ambient heating, efficient usage in a combustion motor without having to adjust for advanced timing issues, or adjusting map sensors. The oxygen can literally undo the gains produced in burning straight HHO in a combustion motor. I'm going to be making another video on the different uses of the hydrogen gas flame.

Here is one of the Active (+) stainless plates. These are laser precision cut by hho-research.com.au . Unless you hire them to build your cell, you will need to either sand blast or use 60 grit wet/dry sand paper (as i did) to score and increase the surface exposure of the stainless sheet.

Here is a shot of one of the press-cut gaskets from hho-research. Note there is a small channel at the top leading to one side or the other, allowing you to direct the gases to one or the other side.

Then a laser cut membrane goes in between yet another gasket and then the next stainless sheet. Shims are used to keep the membranes from falling into the adjacent gasket channels on each side appropriately.

Knowing that neg produces hydrogen and pos produces oxygen, you can build your cell to separate the gas so one channel at the top will receive only hydrogen and the other will receive only oxygen. The end plates come as a un-drilled, un-tapped sheet of acrylic (i think). I think they don't recomment poly-carbonate as they will bust. I'll double check this. I do know that this build is not possible without a drill press and a tap set, unless you have hho-research build your cell for you at an additional cost.

The next step will be incorporating my new 6600 watt electric generator with a GEET reactor and vapour generator. I'm going to add the produced hydrogen to the fuel mixture and attempt to close the loop on the system by driving the electronics with the electric generator. We'll see how that goes. I'm well on my way and i'm going to see it through win or lose. The worst i can end up with is a really efficient electric generator. Maybe combine a small input to the system from a solar panel and i can put it over the top, so to speak. I already have 300watts of 6"x6" triple bus bar solar cells and will be assembling that panel soon too.

The costs are starting to mount up, but it sure is rewarding.

Thanks for watching and reading.

I'll be back.

I'll be back.L&L

TheDude

Comment