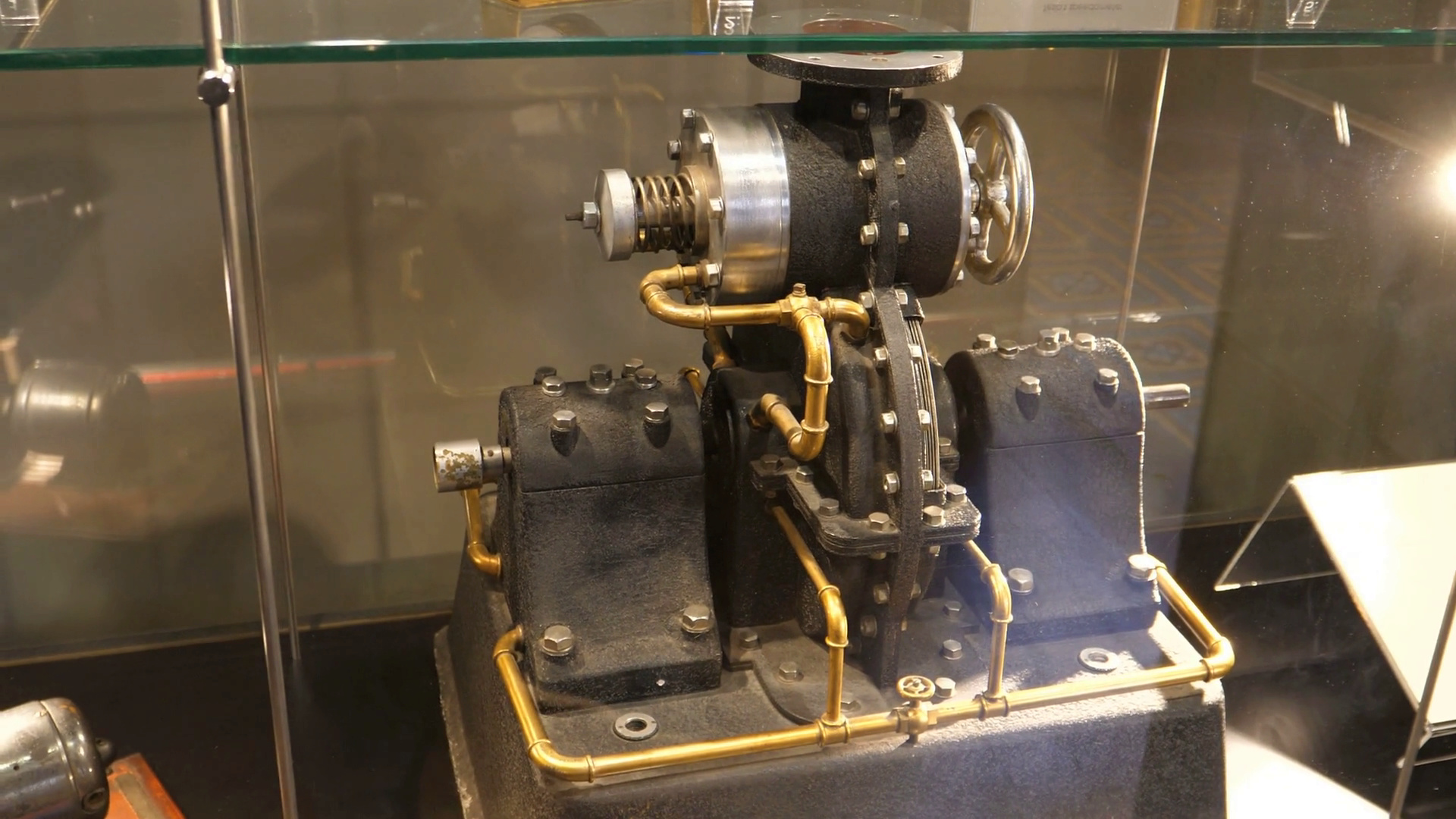

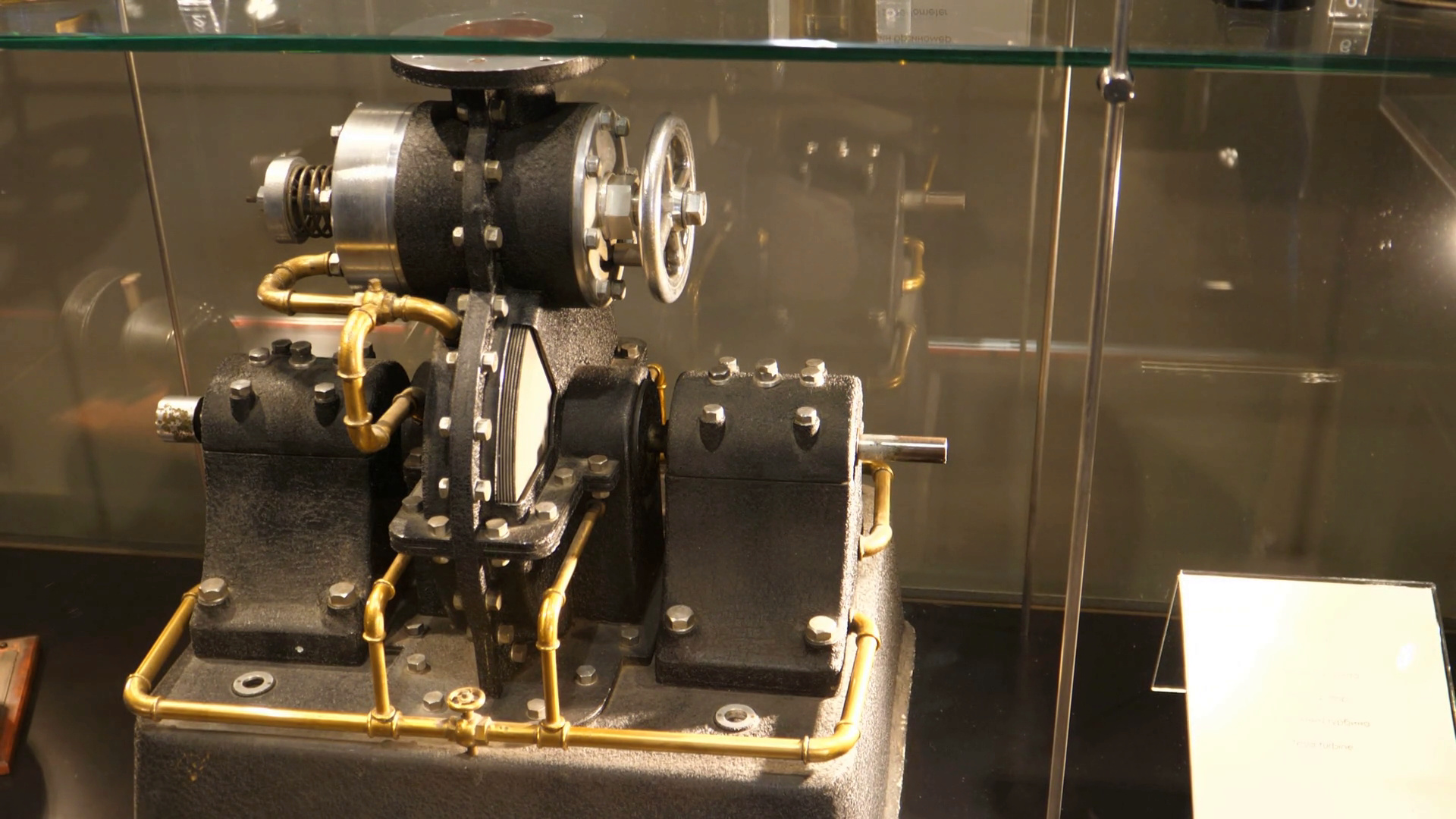

Yeah, I sent them the patent for the Tesla's Mk2 rotor.

This is just a draft that was knocked up last Monday.

I expect big results from these guys!

Proud to have kick started a UK team.

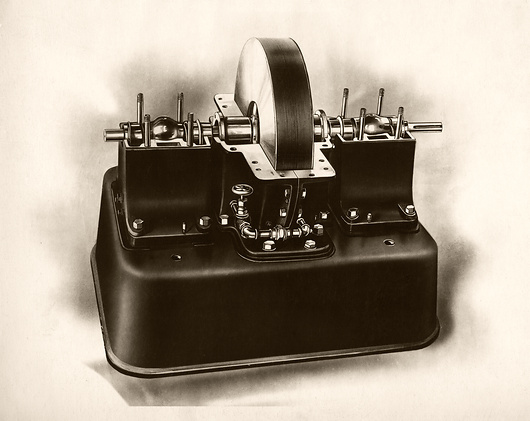

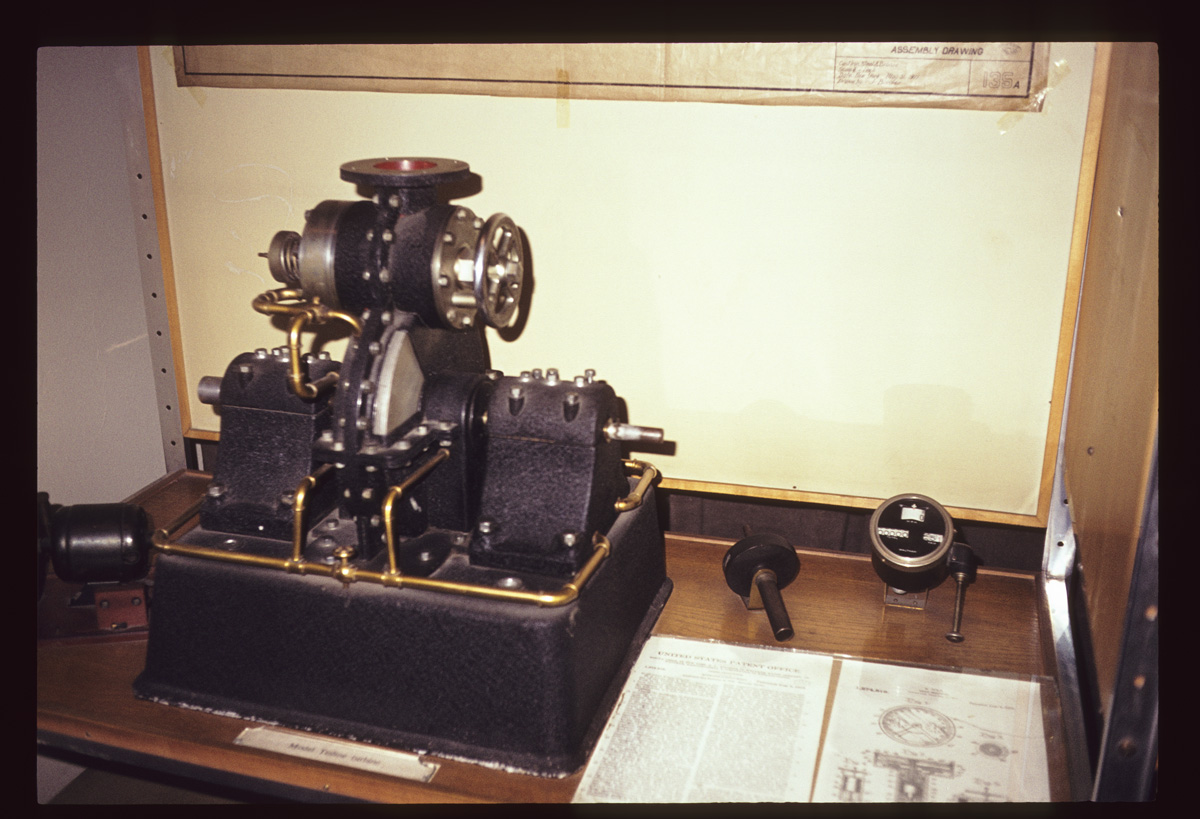

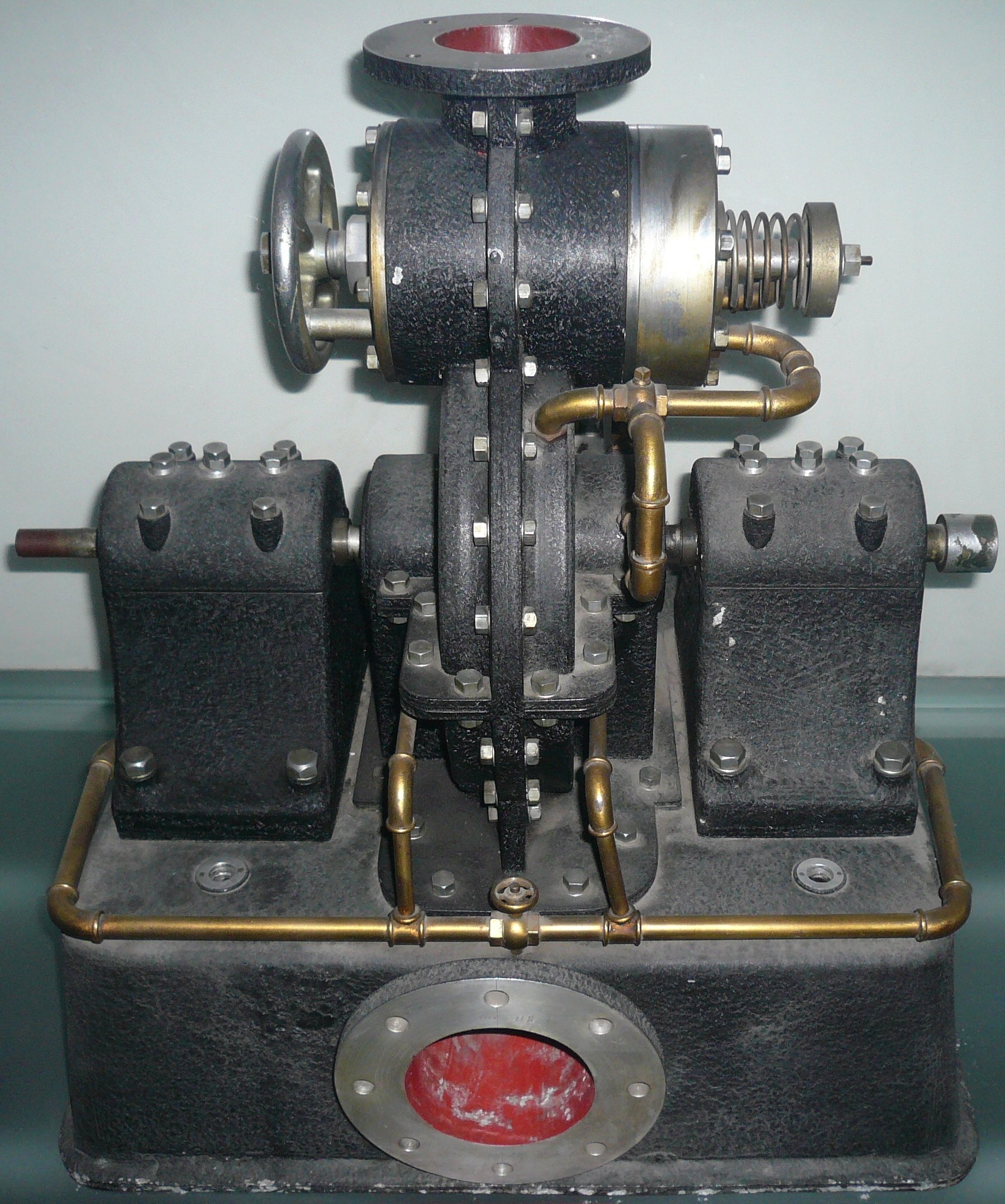

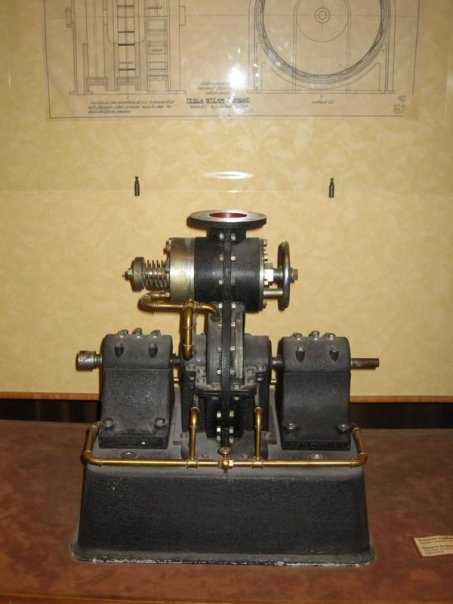

I've been trying kick start replications of Tesla's Monarch of Machines in many countries, as it seems the best way to release a technology like this.

There are at least five now, two in UK, two in US and one in Portugal!

This is just a draft that was knocked up last Monday.

I expect big results from these guys!

Proud to have kick started a UK team.

I've been trying kick start replications of Tesla's Monarch of Machines in many countries, as it seems the best way to release a technology like this.

There are at least five now, two in UK, two in US and one in Portugal!

Comment