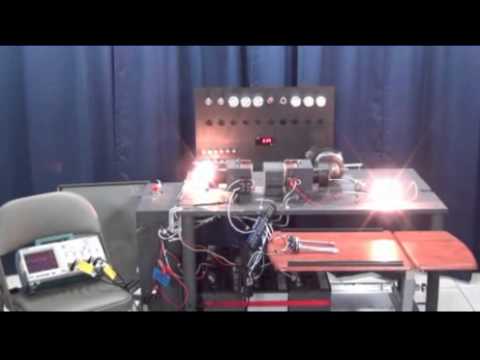

Gap power video's

http://www.gap-power.com/GAP-POWER-M...21%201K562.mp4

http://www.gap-power.com/GAP-POWER-M...%205-27-21.mp4

http://www.gap-power.com/GAP-POWER-M...ectifier-A.mp4

http://www.gap-power.com/GAP-POWER-M.../TEST%2046.mp4

https://www.youtube.com/watch?v=vCjD...cjOC-&index=12

Announcement

Collapse

No announcement yet.

Motor Generators

Collapse

X

-

It is good to hear you are thinking about this problem. I may not be easy to solve. Our spewing nemesis is trying to disrupt the continuity of a kindly exchange with the goal of poisoning my thread. He goes after the stink of it all (spookie dookie) and must be eliminated.

Anyway I'll finish him later.

The obvious choice for you is to try shorter coils because the longer coil impedance is so great at those frequencies that power (assuming the gap is 1mm) has dropped. You are now in the same general zone as Thane, as he runs 1500hz. Now why have I brought this up? The reason is clear, Thane was struggling to find a coil that produces a good amount of power and has used a shorter coil. He use to use those big balls of wire like you use but explained that he could not get the amps.

Try 500 ft and put them all in parallel. This will dramatically change the impedance. You are not running 1500hz like Thane, you are running a little lower (1100hz)

Earlier this week you mentioned that you needed to rewind the 12 strand coil? You must have lost all of your old coils or they don't fit the new machine. Or pull 12 magnets on each bank or set the gap to under 3/16"

Originally posted by Turion View PostI thought I posted these results here, but possibly not.

Testing of three different individual coils.

Iron core 35 v @ .4 amps

A pair of these coils produced .8 amps at 96 volts across the load. I am having a hard time understanding why the same pair produces 130-140 volts across the load at 1.5 -1.9 amps on the older machine. The only difference is 12 magnets on the old rotor rather than 24. Same size rotor. Same RPM. Same strength of magnets.

New permalloy core 33 v @ .4 amps

A pair produces about the SAME as a pair of iron core coils, but without the heat.

Extended permalloy core 14 v @ .25 amps. Still working on trying to get it to go farther in. Lots to do and no time to do it. Trying to understand the different results on the two different machines.Not to be trusted. Bye is poison.Originally posted by bistander View Post

HI Turion,

There I was trying to help. Offer is still there. Got a scope?

bi

Leave a comment:

-

Originally posted by Turion View PostI thought I posted these results here, but possibly not.

Testing of three different individual coils.

Iron core 35 v @ .4 amps

A pair of these coils produced .8 amps at 96 volts across the load. I am having a hard time understanding why the same pair produces 130-140 volts across the load at 1.5 -1.9 amps on the older machine. The only difference is 12 magnets on the old rotor rather than 24. Same size rotor. Same RPM. Same strength of magnets.

New permalloy core 33 v @ .4 amps

A pair produces about the SAME as a pair of iron core coils, but without the heat.

Extended permalloy core 14 v @ .25 amps. Still working on trying to get it to go farther in. Lots to do and no time to do it. Trying to understand the different results on the two different machines.Trying to understand the different results on the two different machines.HI Turion,Originally posted by bistander View PostHi Turion,

Be interesting to know coil span overlays pole pitch. Let's see, you have 4 poles per coil. Hmmm. Core and magnet diameters are what, 3/4 inch? Don't have the core circle diameter or the outer coil diameter. What would be really helpful is a waveform of generated voltage. Got a scope? But you're not big on sharing data or doing a simple requested test.

Post up what you will. I'll be watching. Good luck.

bi

There I was trying to help. Offer is still there. Got a scope?

bi

Leave a comment:

-

I thought I posted these results here, but possibly not.

Testing of three different individual coils.

Iron core 35 v @ .4 amps

A pair of these coils produced .8 amps at 96 volts across the load. I am having a hard time understanding why the same pair produces 130-140 volts across the load at 1.5 -1.9 amps on the older machine. The only difference is 12 magnets on the old rotor rather than 24. Same size rotor. Same RPM. Same strength of magnets.

New permalloy core 33 v @ .4 amps

A pair produces about the SAME as a pair of iron core coils, but without the heat.

Extended permalloy core 14 v @ .25 amps. Still working on trying to get it to go farther in. Lots to do and no time to do it. Trying to understand the different results on the two different machines.

Leave a comment:

-

Discussion of Lenz on one of the forums:

That is an awful long time of 6.2 milliseconds for a DC switch to close, and for the magnetic and electrical field to "build" in a line.

In my pulse motors, the pulse is usually 1 or 2ms...

A full half-wave of a 60hz sinewave is 8.3ms...(!)

I would assume after that 6.2ms is when it becomes saturated sort of, and now the third inherent component of electrical flow; heat, appears.

Also will assume the electrical flow of electrons comes first, then followed by the magnetic field.

And when Tesla says "to build", that means the magnetic field finally becomes strong enough to do some work, like pull a piece of iron or push a magnet

Anyways if so, this makes it very clear and believable how you can make a rotor of permanent magnets lets say 16 of then NSNSNSNSNSNSNSNS and whip them around past a coil, then load the coil or short it out, and the loading does not cause lenz law braking, instead speeds up rotor under loading.....

as if it takes 6.2 milliseconds for magnetic field to build when a DC switch closes, then you would assume a similar time of 6.2ms it takes for the lenz braking effect caused from backemf forces of the loaded coil to manifest with enough force to pull that rotor magnets backwards against rotation.

If so, then the RPMS of those 16NS rotor magnets in a rotor against the loaded coil can be adjusted to be just the right "window" of RPMS to be where the upcoming "trailing" magnet is what gets hit by the backemf lenz forces, not the magnet that just induced the loaded coil in first place to be creating the backemf forces that are "supposed" to pull the rotor magnets backwards against rotation braking it.

So instead the upcoming "next magnet in rotation" gets hit with the backemf forces....and if that is of reverse polarity to the "leading" magnet then its going to push or pull that rotor forward in rotation, speeding it up. Seems like all it takes is simple mathematical calculation of the time between magnets at certain RPM (or magnet edges) to figure out just how fast to rotate the rotor.

I see how with a coil, both the speed of travel and the magnetic field manifestation would decide the time that lenz law braking forces would come into force. But ball park it should be around that 6.2milliseconds I bet.

Impedance of loaded coil also factor as a 100ohm coil is going to take longer for a strong backemf magnetic field to develop than a 10 ohm coil....

Leave a comment:

-

You misunderstood. With the correct circuits 90% of the convention motor design can be recovered. Regular induction motors can not collect a dc collapsing field so easy.Originally posted by bistander View Post

That's stupid. 100% of the "electrical current from the battery is returned" to every battery all the time. Fact.

bi

It's not nice to say stupid in all your posts. You are a very evil person, full of puss and sick venom . Induction motor design is outdated like you grandpa

. Induction motor design is outdated like you grandpa

Induction motors are not pulse dc engines.

I can feel the unclean spirits pouring off of your toxic comments and feel dirty afterward.

Last edited by BroMikey; 02-25-2022, 04:43 PM.

Leave a comment:

-

-

http://www.free-energy.ws/pdf/magneteal_industries.pdf

https://documents.pub/reader/full/bo...on-user-manual

Magnipulsion engine. Soon to be ruling the world. Another false promise.

Another false promise.

Last edited by BroMikey; 02-24-2022, 07:21 PM.

Leave a comment:

-

Yes I follow your comment for the stone-age geometry. A dazzling display of early theory and math. All true, but not the whole truth. At least I can follow your thinking on c cores saving copper.Originally posted by bistander View Post

Ampere's Law.

the frame section as seen on early vintage dynamos.

It took a few years ........to save half the copper.

So build it and see it for yourself.

bi

You are safe and backup with the ancient copy and paste job. I almost forgot that detail often presented in lower classroom studies when DC motors went AC.Last edited by BroMikey; 02-24-2022, 04:45 PM.

Leave a comment:

Leave a comment: