Originally posted by Ufopolitics

View Post

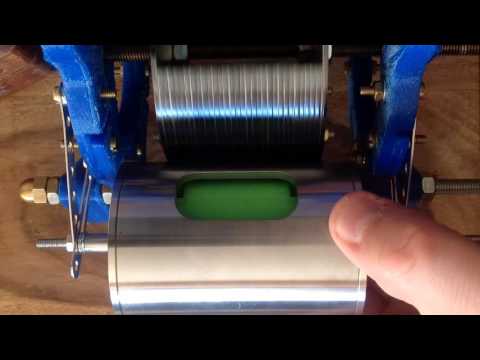

It should to be fun getting one. You know a square arc shaped Neo that is tapered.

Leave a comment: