Originally posted by Ufopolitics

View Post

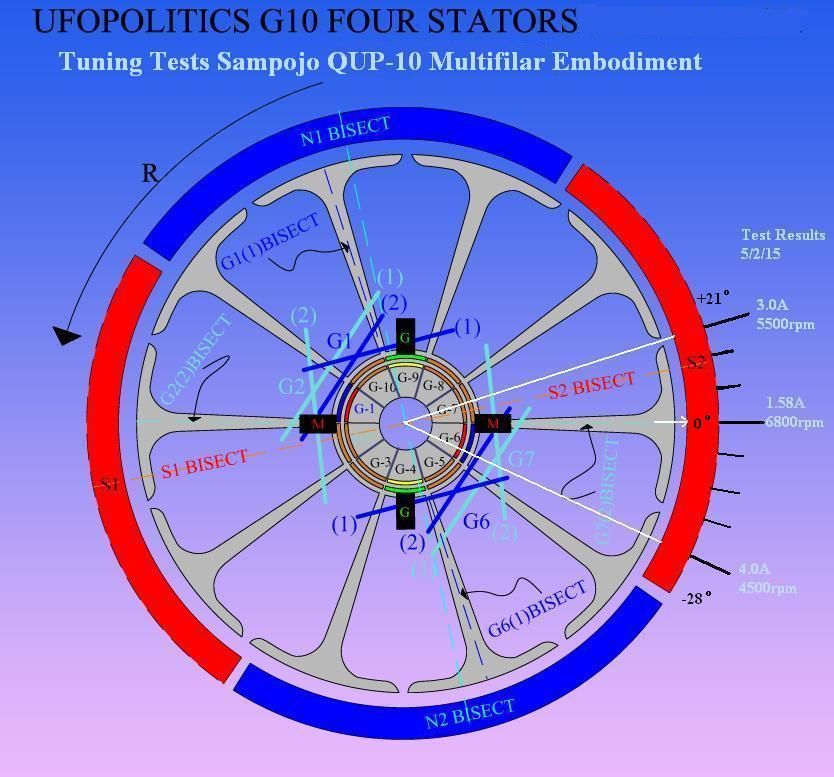

I didn't want to go into fractions of degrees when broad principles establishes the point, but I can.

I referred to 'pole angles' as 'A' being 1/28 of 360°...which is 12.857°

The angle between P1C2 and P2C1, I referred to this as 'Z' being '5A' ...which is 64.285°

I notice you have indicated the brush width as being approximately 50% of the comm segment width, not full width as it is in my 12 pole motor. This reduces the sweep angle 'sA' before P2 disconnects from 12.857° to...6.428°

So

X + Z + sA + Y = 7A = 90°

Substituting

X + 64.285° + 6.428° + Y = 90°

X + Y = 19.287°

X is tunable in the region of 5° from previous posts AND

Y wants to be in the region of 20°

Which adds to more than 19.287°

Of course for the 12 pole 2 stator motor X and Y can not squeeze up to accommodate -

'Z' being '5A' being 5/12 of 360° ...which is 150°

The brush width being the comm width 'sA'...which is 30°

So

X + Z + sA + Y = 180°

Substituting

X + 150° + 30° + Y = 180°

X + Y = 0°

And therefore is not achievable.

However the 12 pole motor configured as '4 pole pairs' does work, I've done it. But it is determined by the flawed geometry to be inefficient as the leading coil remains energised past the magnet bisector and therefore contributes drag.

Good Hunting

mark

)... to start shooting at me,the bringer of this type of winding...and who have a few naked, Imperial Rotors in his Garage...plenty of wire and many, many Geometrical Angle Rulers, and software CAD'S , HD Cameras to demonstrate you ARE WRONG...

)... to start shooting at me,the bringer of this type of winding...and who have a few naked, Imperial Rotors in his Garage...plenty of wire and many, many Geometrical Angle Rulers, and software CAD'S , HD Cameras to demonstrate you ARE WRONG...

...because you are just adding the 'switcher displacement angle' to the magnetic interactions angle...just because the "switch" is outside the 64.85 degrees from the EM Interactions taking place.(see image below as the one you are referring to):

...because you are just adding the 'switcher displacement angle' to the magnetic interactions angle...just because the "switch" is outside the 64.85 degrees from the EM Interactions taking place.(see image below as the one you are referring to):

...but they further on 'concluded' without any substantial proof that the FLOW will take place FROM NORTH TO SOUTH...as seen the arrows above following a ONE WAY direction...

...but they further on 'concluded' without any substantial proof that the FLOW will take place FROM NORTH TO SOUTH...as seen the arrows above following a ONE WAY direction...

Comment