Originally posted by sampojo

View Post

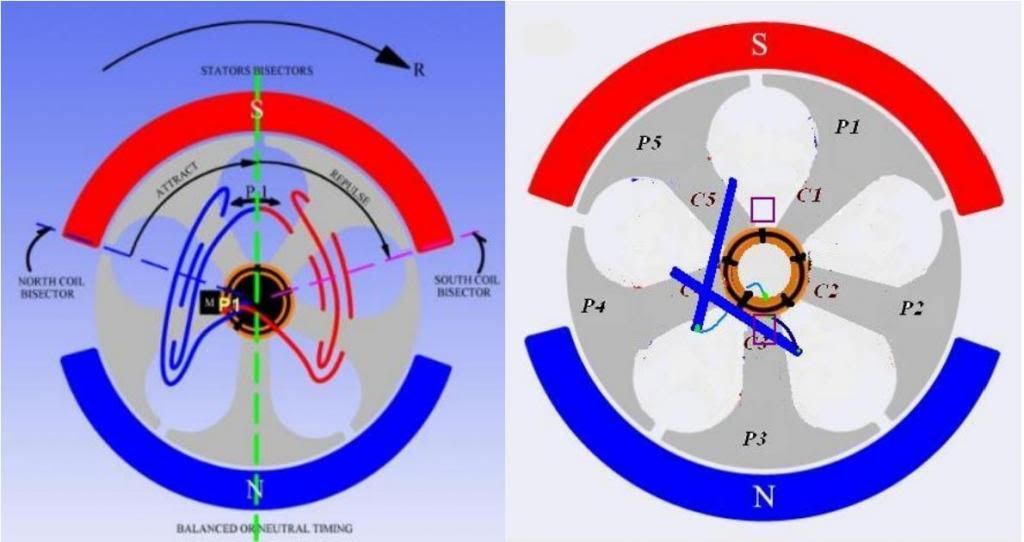

My design is the Singular Coil that is the same size as the magnet or a little bigger than the magnet... (NOT a one pole coil, like AN3)...

One pole coil is only for the 3pole motor/no choice .

AN2, my design, the coil was the same size as the magnet. The singular coils covered two poles per coil.

Keep it Clean and Green

Midaz

From the original image below, the singular coils are the same size as the magnet On repulsion mode... Highest TORQUE with high RPMs

Comment