Thanks UFO.

One way or another I will CAD this tomorrow to demonstrate what I'm saying.

There is one thing I should seek absolute clarity on...and this could be the difference between what you're saying and what I'm understanding and this would remove all the frustration.

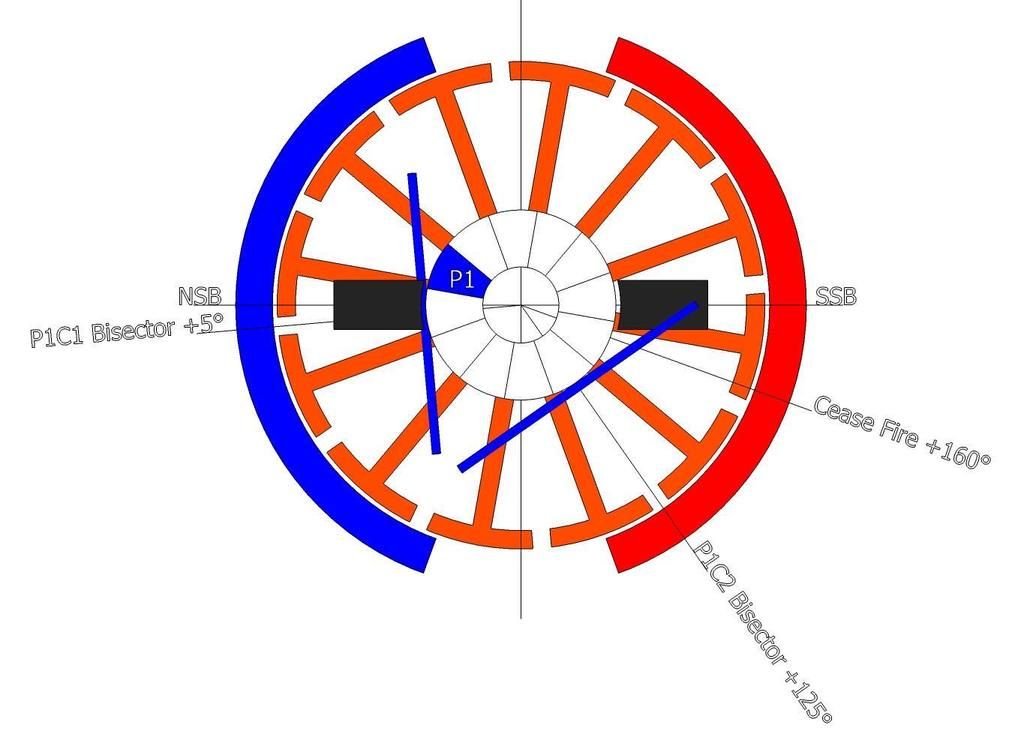

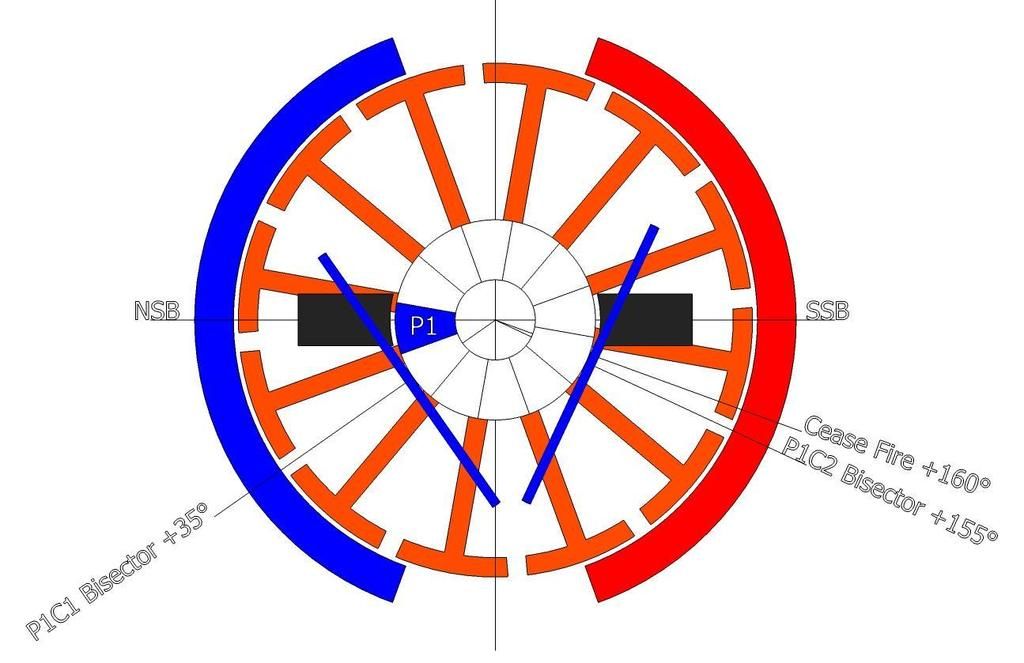

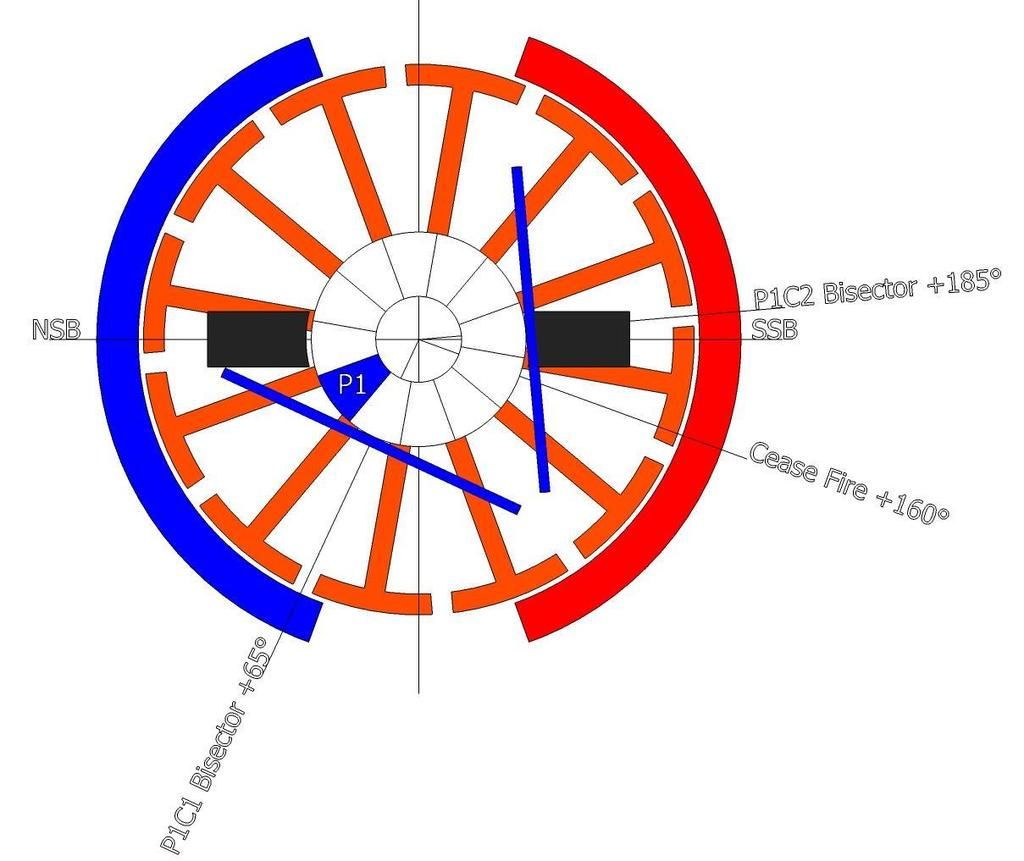

When we say 'connecting' or 'start firing' we mean the comm is just entering the brush...

When we say 'disconnecting' or 'cease firing' we mean the comm has fully left the brush...

Also, the only thing that is not completely accurate on my CAD schematic is the brush is not drawn at 30º which I will correct when I post my next image...it fully covers the face of the comm segment which is important for visualising the sweep angle of the comm across the brush from connection to disconnection...if I'm understanding those terms correctly.

And UFO, I mean no disrespect when I refer to 'Theory'...it's what you give to someone to put into practice. My point which I hope to clear up when I post my schematic is the theory doesn't work in practice for the 4 pole pairs on a 12 pole rotor.

Happy Hunting

mark

One way or another I will CAD this tomorrow to demonstrate what I'm saying.

There is one thing I should seek absolute clarity on...and this could be the difference between what you're saying and what I'm understanding and this would remove all the frustration.

When we say 'connecting' or 'start firing' we mean the comm is just entering the brush...

When we say 'disconnecting' or 'cease firing' we mean the comm has fully left the brush...

Also, the only thing that is not completely accurate on my CAD schematic is the brush is not drawn at 30º which I will correct when I post my next image...it fully covers the face of the comm segment which is important for visualising the sweep angle of the comm across the brush from connection to disconnection...if I'm understanding those terms correctly.

And UFO, I mean no disrespect when I refer to 'Theory'...it's what you give to someone to put into practice. My point which I hope to clear up when I post my schematic is the theory doesn't work in practice for the 4 pole pairs on a 12 pole rotor.

Happy Hunting

mark

Comment