Gary

No bad! Should be exciting!

Is the Timing the same as the factory?

Do to the wind of my design, "Singular Coil", the wind only interacts with one magnet for the 5 rotor pole motor. The timing of the positive input may need some adjustments. As you get closer to TDC, the torque and RPMs will increase. For adjusting the positve input timing, I thought about the RPMs & torque vs power consumption. RPMs & torque vs power consumption equation should be as balanced as possibe to the OEM.

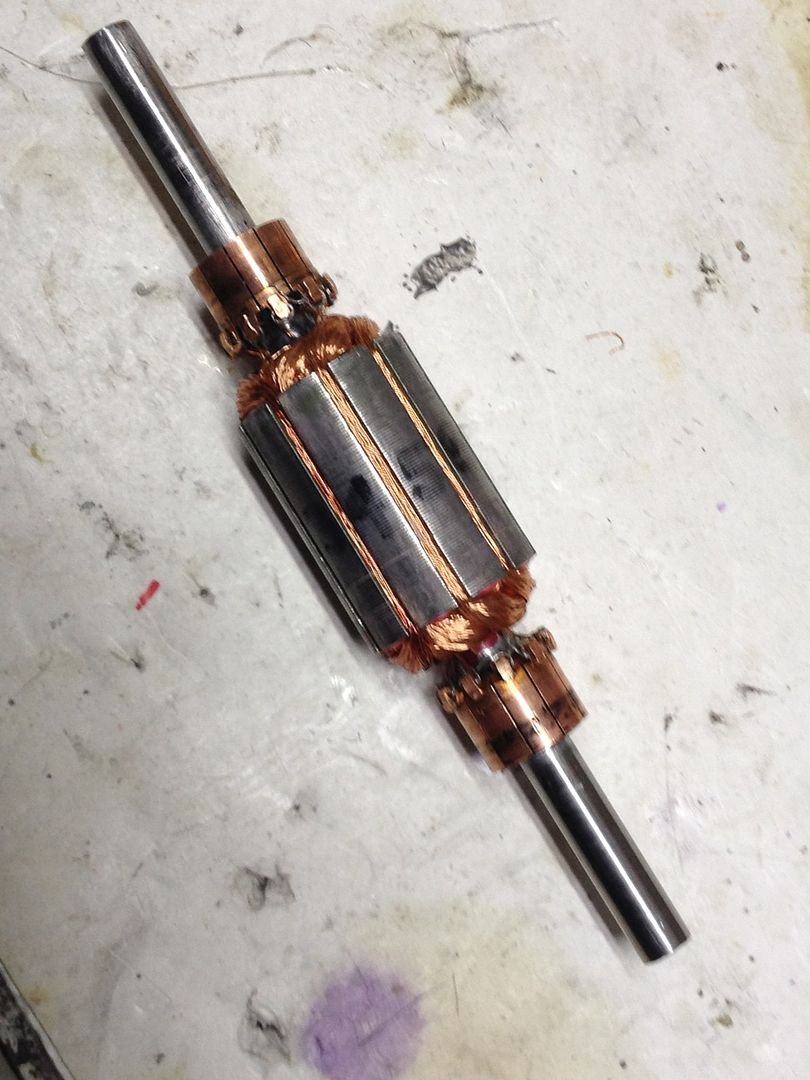

Do you have a clear pic of the winds for my design? The pic is too blurry for a closeup view.

Power to the people

Keep it Clean and Green

Midaz

No bad! Should be exciting!

Is the Timing the same as the factory?

Do to the wind of my design, "Singular Coil", the wind only interacts with one magnet for the 5 rotor pole motor. The timing of the positive input may need some adjustments. As you get closer to TDC, the torque and RPMs will increase. For adjusting the positve input timing, I thought about the RPMs & torque vs power consumption. RPMs & torque vs power consumption equation should be as balanced as possibe to the OEM.

Do you have a clear pic of the winds for my design? The pic is too blurry for a closeup view.

Power to the people

Keep it Clean and Green

Midaz

...do some simple math there...the overall amps increase is only 0.55 amps (1.3-0.750), while the RPM's is about TRIPLE the Symmetric Motor.

...do some simple math there...the overall amps increase is only 0.55 amps (1.3-0.750), while the RPM's is about TRIPLE the Symmetric Motor.

Ran my quadfilar version for about a minute and it was smoking that new epoxy and up to 120 degF super fast. Resistance per coil was .6-.7 ohm I think. 3-4Amp draw, when my well running dual stator double rotor of this style only was taking 1.3A.

Ran my quadfilar version for about a minute and it was smoking that new epoxy and up to 120 degF super fast. Resistance per coil was .6-.7 ohm I think. 3-4Amp draw, when my well running dual stator double rotor of this style only was taking 1.3A. . Think I got it right where I want it.

. Think I got it right where I want it.

Comment