For the time being

Hi UFO

It wasn't clear in my last post, but the intention is to address the timing/amps draw in the next motor rebuilds and not this one.

If this is the max power timing for this build of this motor then I will go with that.

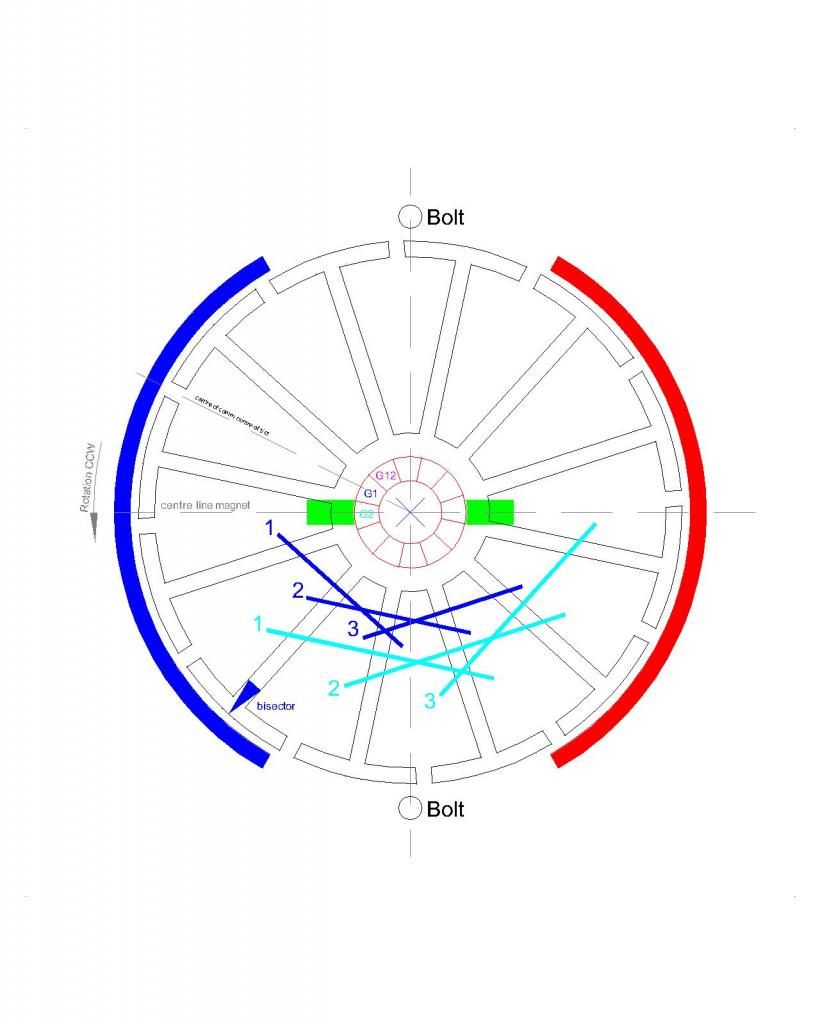

The brush boards are mounted on the motor end caps, timing adjustment would be by rotating the end caps given by the limits of the fixing bolts positioned between the north/south magnets.

My uncertainty would be how to rotate both end caps to the same position to ensure perfect alignment...failing that...timing is defined by how inaccurately the two boards are positioned relative to each other. In practice I feel this margin of error is probably quite small.

best regards

mark

Hi UFO

It wasn't clear in my last post, but the intention is to address the timing/amps draw in the next motor rebuilds and not this one.

If this is the max power timing for this build of this motor then I will go with that.

The brush boards are mounted on the motor end caps, timing adjustment would be by rotating the end caps given by the limits of the fixing bolts positioned between the north/south magnets.

My uncertainty would be how to rotate both end caps to the same position to ensure perfect alignment...failing that...timing is defined by how inaccurately the two boards are positioned relative to each other. In practice I feel this margin of error is probably quite small.

best regards

mark

...and it should draw much less amps there. From that point on towards South He would be timing it towards a higher Attraction Mode...decreasing to even more amps...but sacrificing power/torque and speed.

...and it should draw much less amps there. From that point on towards South He would be timing it towards a higher Attraction Mode...decreasing to even more amps...but sacrificing power/torque and speed.

Comment