Search for parts

Thanks Dana and UFO.

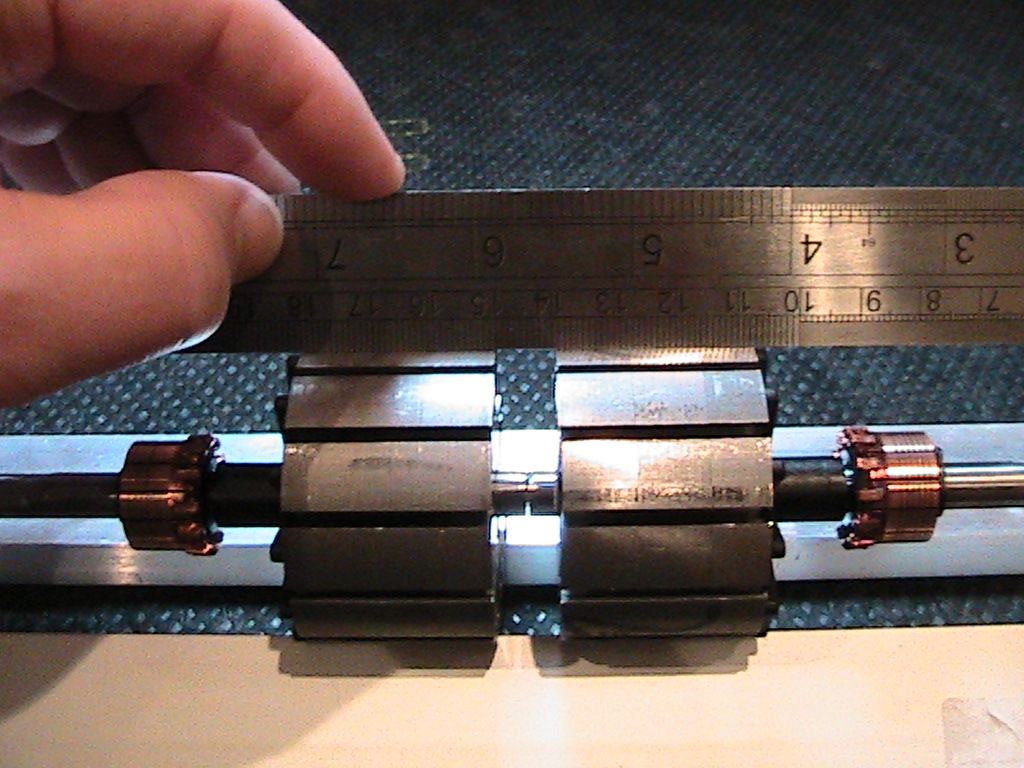

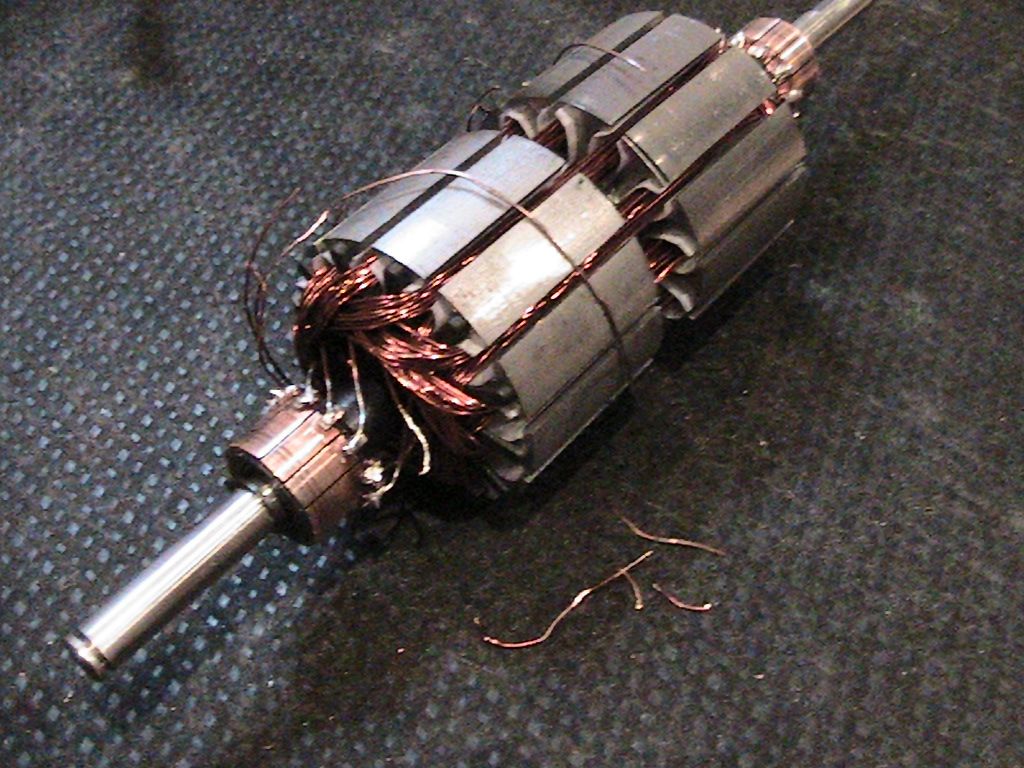

I have done a reasonably thorough search for DC motor parts here in the UK and it is driving me insane. ‘Parts’ appears to mean brushes and bearings…I found one supplier for (one radius size only) arc magnets which are slightly smaller on the radius to my motor and about half or less on the arc angle…and that’s it. No comm supplier or laminates. I even had problems today finding M3 bolts so will be making my own to hold the casings together. Magnet wire is in abundance, nothing comes up for hedges and those nifty plastic stars at the top and bottom of the stack…who knows ?

So any helpful clues on where to source this stuff would be gratefully received…especially hedges as I had a suspicion it could have been leakage out the slot that pulled the wire off.

I also checked out Imperial motors and find no reference to kits so a link would be good please.

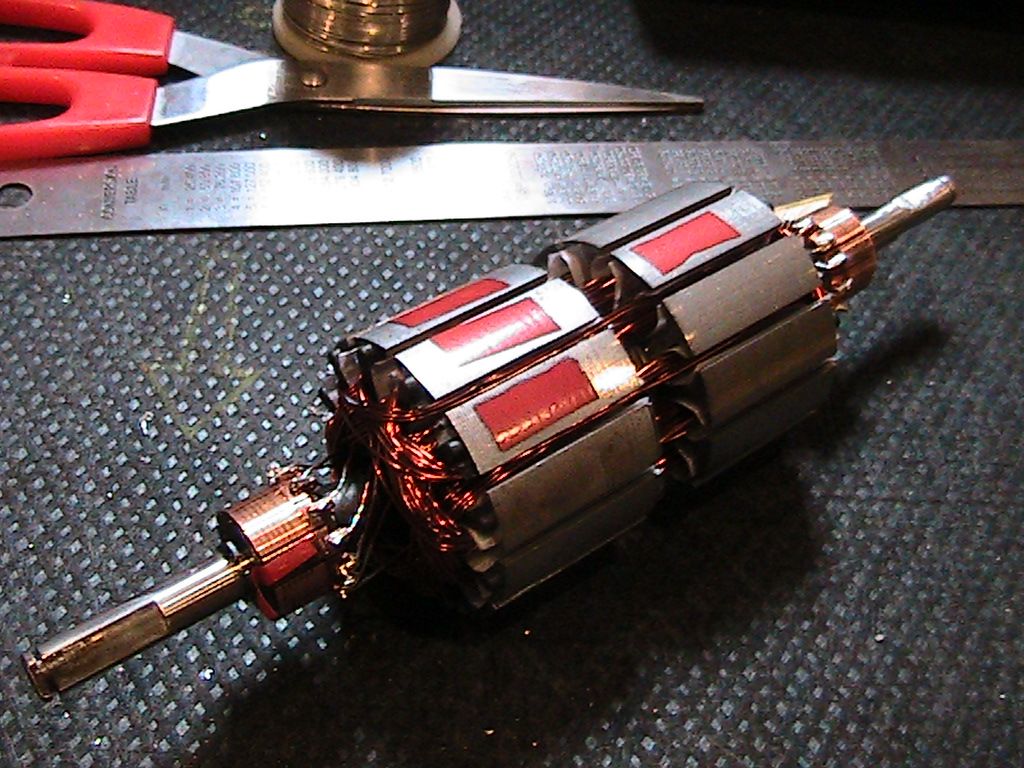

I shall rewind this motor with more finesse using 0.425mm (solderable) so I can ensure proper connection and lever those tabs up for a good mechanical fix. I should be able to get 10m of wire per group. The wire is quoted at 0.121 ohms/m. Hopefully that sounds good ?

Apologies UFO, When you say add these…do you mean add them after the heavier wire or at the same time…bifilar style ?

You will not be surprised that I didn’t do this…but I will next time.

Thanks UFO…I had a clear idea of what I wanted to achieve and I had studied your videos to try and embed this completely different methodology. When you consider that I did this with no background in the subject, no tools apart from a screwdriver to take the original motor apart and a soldering iron to put the new one back together…AND…copious amounts of insulation tape. It shows what can be achieved once the hard work has been done. The hard work being your invaluable input to this subject.

Thank you all.

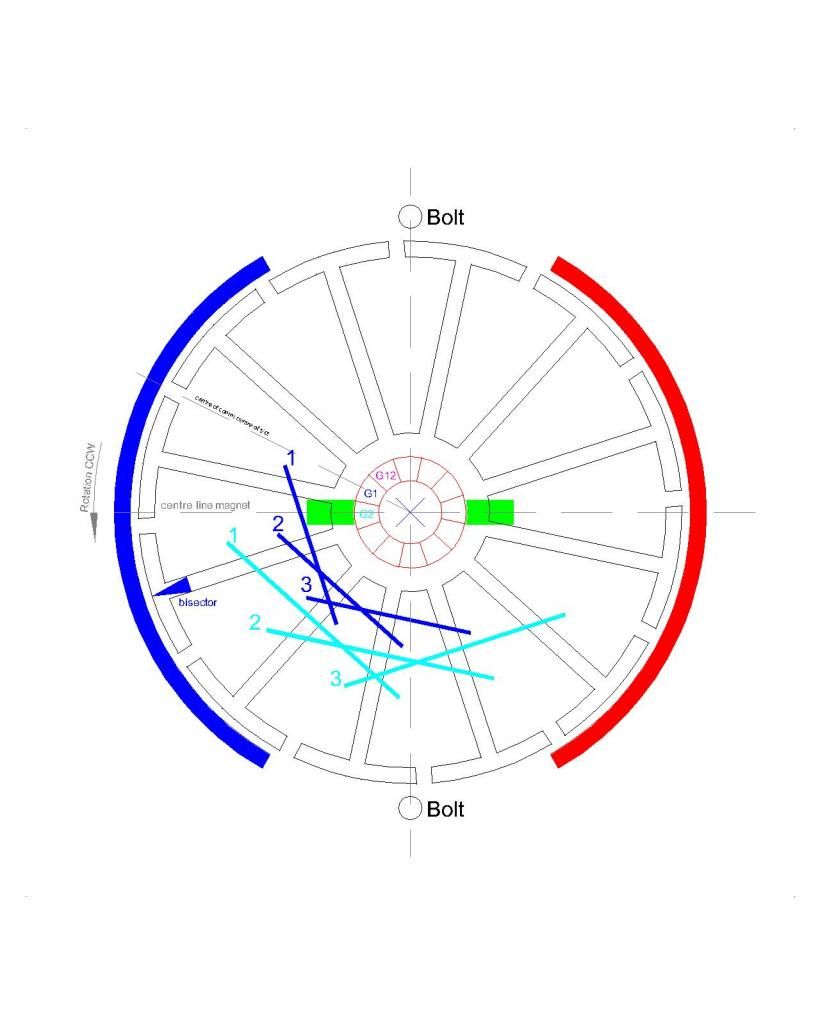

Now I knocked this up at work today just to show the minor differences in UFO’s diagram and my motors geometry. This is how I wired it –

12polemotor.jpg Photo by huntingross | Photobucket

A described before the G1 comm is coming onto the brush with G1 Coil 1 bisector past the midpoint of the magnet.

mark

Thanks Dana and UFO.

Originally posted by Ufopolitics

View Post

So any helpful clues on where to source this stuff would be gratefully received…especially hedges as I had a suspicion it could have been leakage out the slot that pulled the wire off.

I also checked out Imperial motors and find no reference to kits so a link would be good please.

Originally posted by Ufopolitics

View Post

Originally posted by Ufopolitics

View Post

Originally posted by Ufopolitics

View Post

Originally posted by Ufopolitics

View Post

Thank you all.

Now I knocked this up at work today just to show the minor differences in UFO’s diagram and my motors geometry. This is how I wired it –

12polemotor.jpg Photo by huntingross | Photobucket

A described before the G1 comm is coming onto the brush with G1 Coil 1 bisector past the midpoint of the magnet.

mark

...What am trying to say is...do not spent too much money in an Imperial just to run a very "Toxic Generator Type"...if you decide to buy an Imperial, plan to use it on a small EV or even an Electric Super Bike...

...What am trying to say is...do not spent too much money in an Imperial just to run a very "Toxic Generator Type"...if you decide to buy an Imperial, plan to use it on a small EV or even an Electric Super Bike...

Comment