Originally posted by GChilders

View Post

Is hard for me to understand by the way you are describing it, I am sorry.

You are mentioning Three Coils?...but referring to the Five Poles?...or you meant Three Poles for each Pair of Coils?

One question, did you watch my latest two videos? plus this one below?:

https://www.youtube.com/watch?v=RSs2beNfAP8

Can you see the way it goes on this 50 sec 3D CAD?

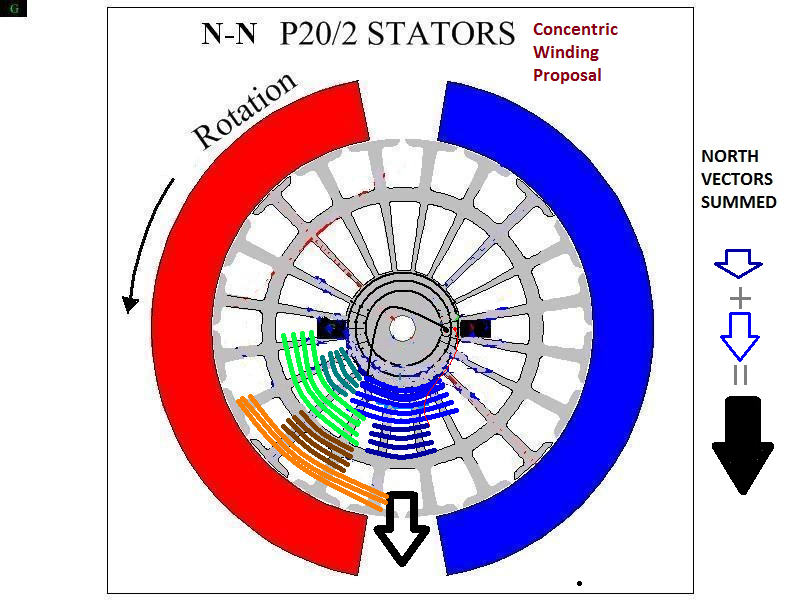

The Upper brush element in Red is Positive, while the black on bottom is negative, both coils Interleave or overlap at a center common Pole...both wound CW...That's your P1...then do P2 in Aqua color exactly the same way as in Diagram below:

[IMG]

[/IMG]

[/IMG]Notice P2 first Coil (right below its starting element) winds exactly on top of P1 Second/end Coil...and so on.

Let me know if you understood now...

Regards

Ufopolitics

handle the hammer with care.

handle the hammer with care.

Comment