a new member here, may be accepted to study here

[/IMG]

[/IMG]

My test driver said she wants to call it Nessie and paint it GreenI don't know why

My test driver said she wants to call it Nessie and paint it GreenI don't know why

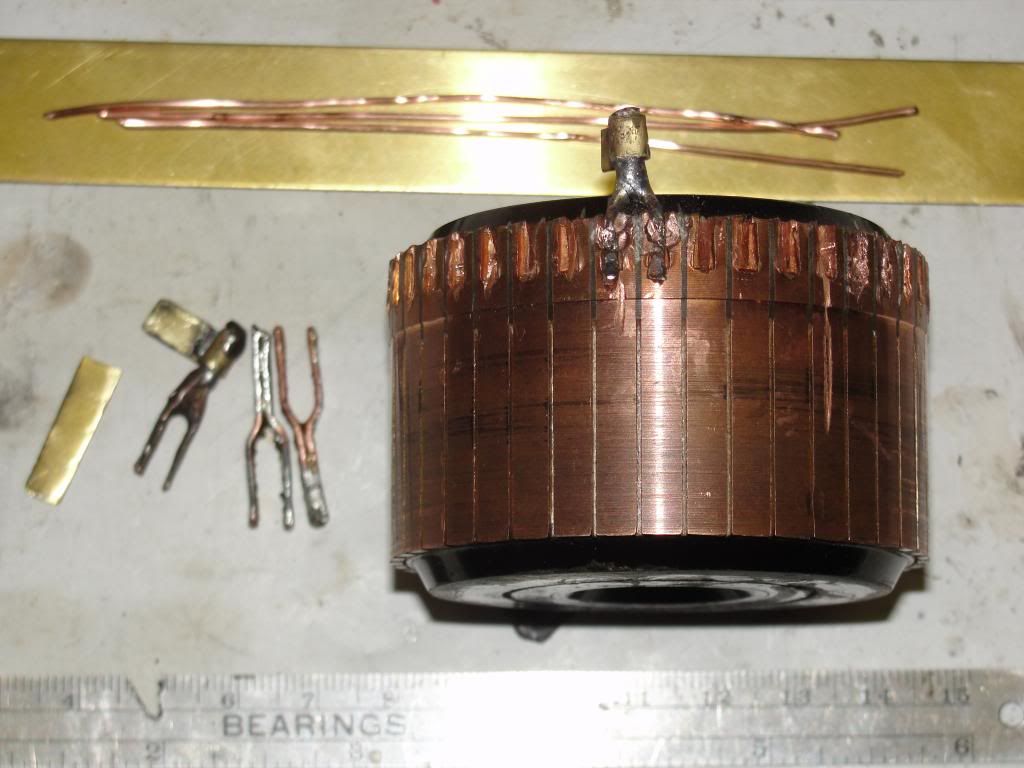

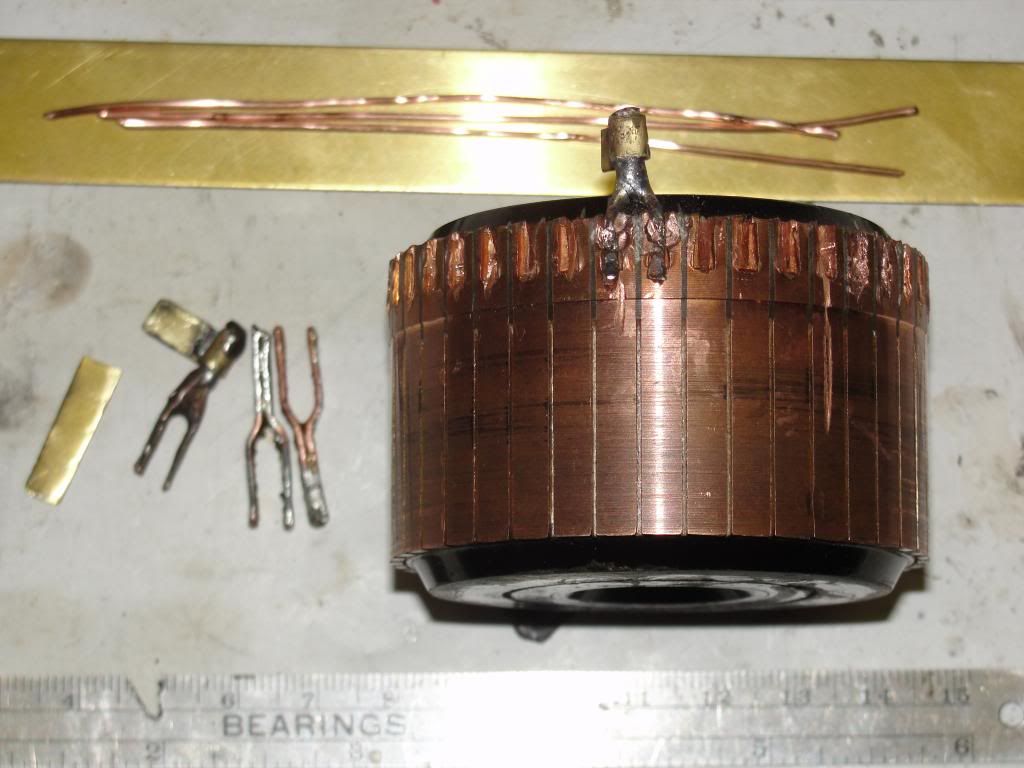

If I do not want to register it must be equal under 250wattsor less this being a 1000w motor after modification it will run @24v or 36v drawing say 5 amps perhaps under load say 6 amps

If I do not want to register it must be equal under 250wattsor less this being a 1000w motor after modification it will run @24v or 36v drawing say 5 amps perhaps under load say 6 amps

Comment