Originally posted by Ufopolitics

View Post

You got a lot of cards up your sleeves! The golf karts are off the chain! We can drive those on the street in Japan. With signal lights, highs & low beams, horn and wipers...

Keep it Clean and Green

Midaz

...Yeah, not seconds, until I install the Imperial Asymmetric...

...Yeah, not seconds, until I install the Imperial Asymmetric...

[/IMG]

[/IMG]

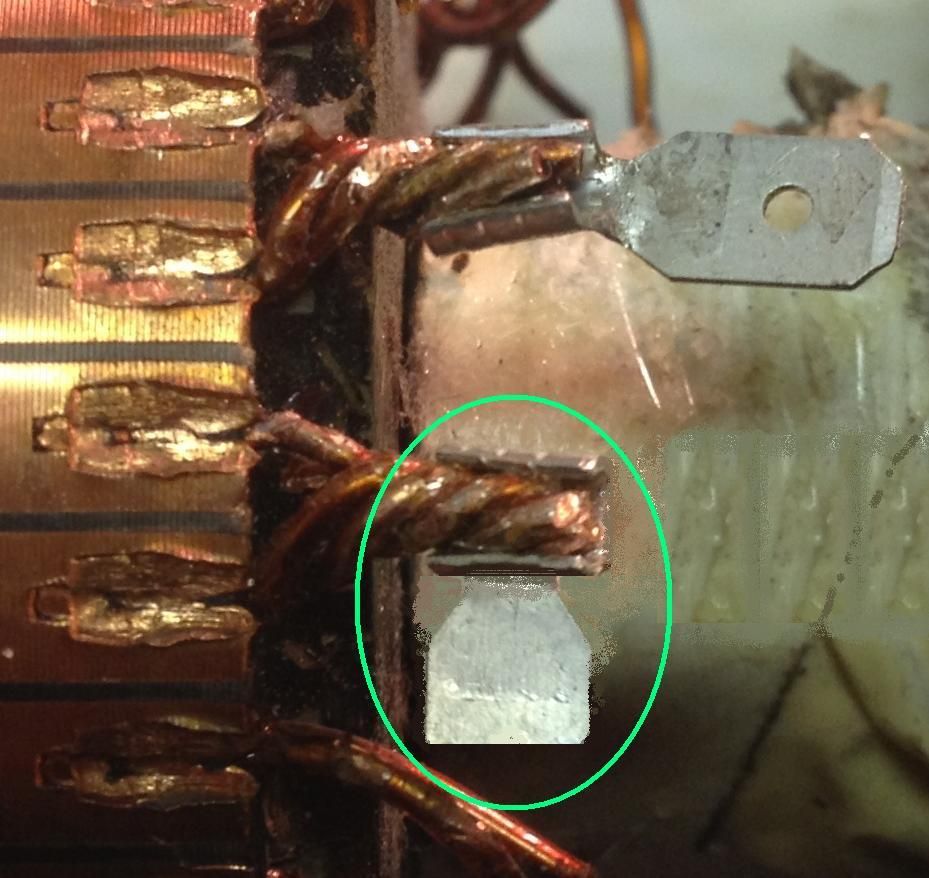

. Pair 3 and Pair 13 shorted. I took necessary care to avoid this situation by keeping the poly paper sheet that the professional winders keep. I kept on checking the poles till I completed ten pairs winding. Till then it was very much alright.

. Pair 3 and Pair 13 shorted. I took necessary care to avoid this situation by keeping the poly paper sheet that the professional winders keep. I kept on checking the poles till I completed ten pairs winding. Till then it was very much alright. ), i found smoke from the rotor. I stopped feeding that voltage and currant to armature. This time I increased the wire length ( and thus the no. of turns) and also the res. hoping that I could run it on 230 v 4 amp.

), i found smoke from the rotor. I stopped feeding that voltage and currant to armature. This time I increased the wire length ( and thus the no. of turns) and also the res. hoping that I could run it on 230 v 4 amp.

.

.

...plus all the centered brackets to hold stator housing to bearings...

...plus all the centered brackets to hold stator housing to bearings...

Comment