Originally posted by GChilders

View Post

Thanks for the comment

I am going to build my own Tricycle it will be made of Plywood

and have 3- 22" Bicycle wheels with double rims I still have to design it yet, it will be driven by the 1000W motor using 24v probably there will be an 11 tooth sprocket on the motor driving a 60 tooth? sprocket fitted onto a 3/4" shaft with a differential probable as shown here

My engineer friend who does all my metal turning said he probably has one from an old Mower or something that he pulled apart some time ago I will be seeing him on Thurs or Friday to look for it in his shed if not I will buy the one above US4145.44 delivered to me in Aus.

I find I am getting better now at winding the motors

I might have to rewire my smaller motors

I finished putting my motor together today and it seems to run very smooth using first 12v then 24v even though it appears to be about 8grams out of balance I was not able to get the speed as yet

Perhaps I will not need to Varnish or balance it

The motor I left the wiring to the Brushes as per original that is there is 4 pairs of brushes i.e. 4 on the top and matching 4 on the bottom it is connected to the battery via 2 pair parallel motor Brushes and 2 pair parallel Generator brushes.

I used a battery box that shows the amps drawn from it

I did some preliminary tests on the motor and the results were running 24v

1. 1 pair only motor poles Draw = 1Amp the yellow DMS shows the pair GP=24v

2. Feeding the GP back into the motor Draw =390ma

3.Using the Monster Driver MP= 1 Amp GP=19.5v

4. 1pair only MP draw =600ma with GP fed back into motor

I took some pics with my IPad they are here

First Trial Run Photos by Kogs1 | Photobucket

I really want to use the Arduino to run this motor But I have to find out how to connect it up

I will keep you all posted as I progress

Kindest Regards

Kogs slowly progressing

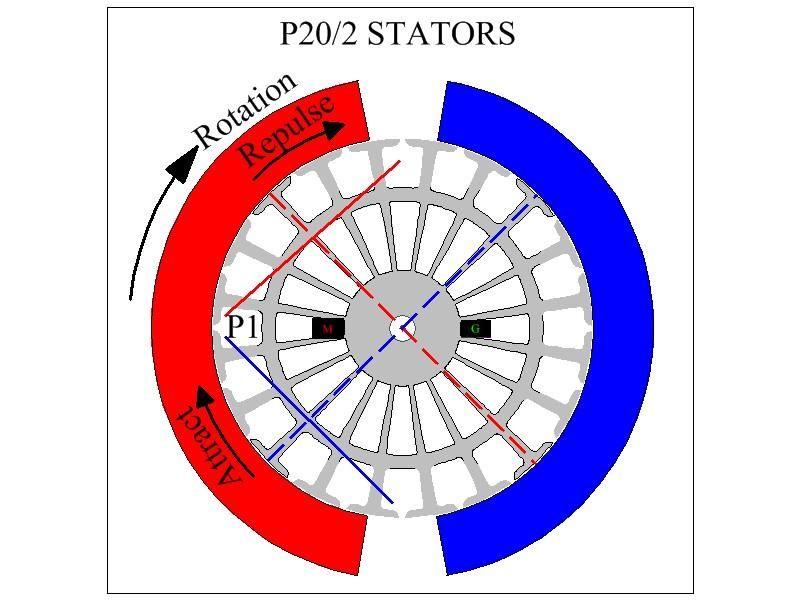

and mentioned they are 180 degree to stator poles. but they are 90 degree to stator pole axis. Sorry for this mistake sir.

and mentioned they are 180 degree to stator poles. but they are 90 degree to stator pole axis. Sorry for this mistake sir. . It ran with about 120 rpm, though the torque was not good.

. It ran with about 120 rpm, though the torque was not good.

How come this happened.

How come this happened.

Comment