sinergicus

Simply, when you short out two coils or connections, you are creating drag and confusion in propelling force. Take your generator contacts and using UFO style diode connection, put them to a large cap or battery, or a bulb. Not letting that coil have anywhere to vent its power is like constipation. Pressure builds but nothing moves. Read the past advice many have given in this thread and you will find many ways to use the coil rather to increase torque or generate power.

Dana

Simply, when you short out two coils or connections, you are creating drag and confusion in propelling force. Take your generator contacts and using UFO style diode connection, put them to a large cap or battery, or a bulb. Not letting that coil have anywhere to vent its power is like constipation. Pressure builds but nothing moves. Read the past advice many have given in this thread and you will find many ways to use the coil rather to increase torque or generate power.

Dana

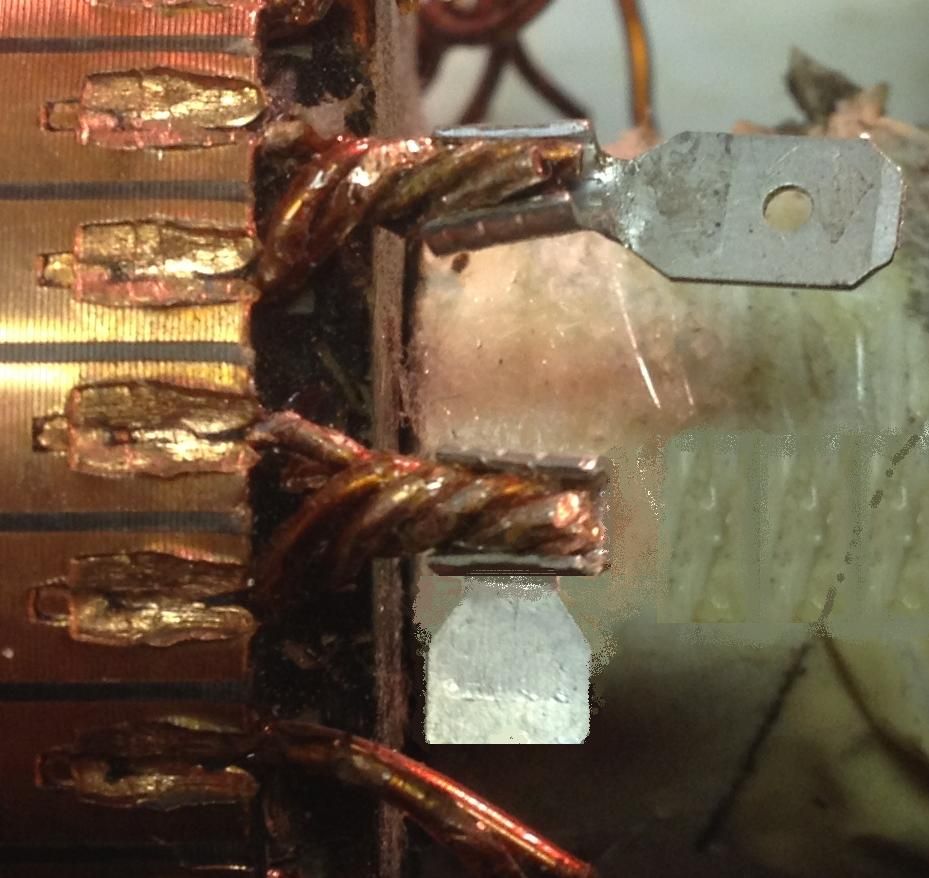

)...would be to buy a pretty nice piece of flat copper lamination (I buy them from guys that have Rain Gutters Fabricating Shops and have tons of scrap pieces and sell them cheap)...and cut "T" shape pieces...using the upper side Horizontal side of the "T" to wrap around wires and clamp them....then using the vertical side of the "T" to be bent as a hook to house your windings...also clamping then with needle nose vise grip players...make a cardboard or paper pattern first to check right lengths first.

)...would be to buy a pretty nice piece of flat copper lamination (I buy them from guys that have Rain Gutters Fabricating Shops and have tons of scrap pieces and sell them cheap)...and cut "T" shape pieces...using the upper side Horizontal side of the "T" to wrap around wires and clamp them....then using the vertical side of the "T" to be bent as a hook to house your windings...also clamping then with needle nose vise grip players...make a cardboard or paper pattern first to check right lengths first.

Comment