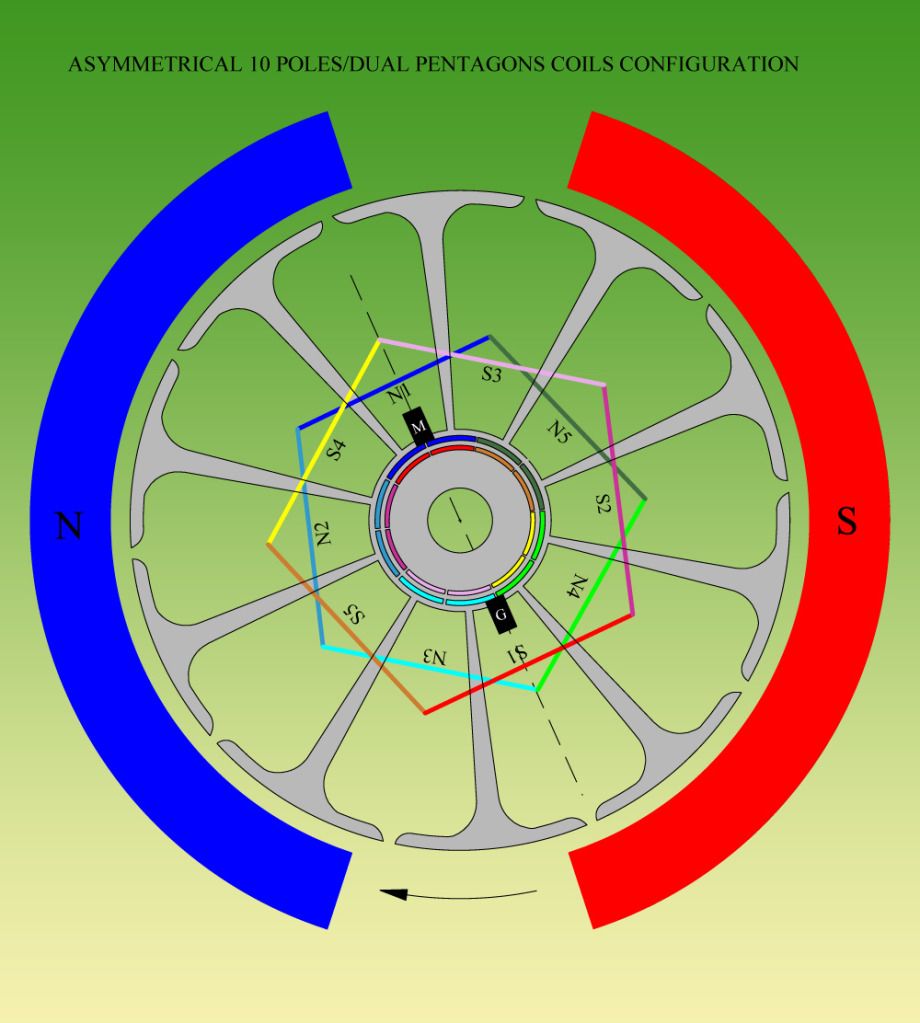

10 Pole windings

Ian,

I hope this is wrong because I finished winding a 10 pole motor yesterday.

I have not finished the holding part for the magnets and housing, so

I have no test results yet. I want to be able to rotate the magnets to

adjust the timing. It makes more sence on this motor to do it this way. I am tring to upload pictures to photobucket but it's not responding. So I will post pictures later.

I wraped three pole at a time, and all my wraps went CCW while looking

at the rotor with the positive end up. Hope that is clear, but my pictures will show it.

Ian,

I hope this is wrong because I finished winding a 10 pole motor yesterday.

I have not finished the holding part for the magnets and housing, so

I have no test results yet. I want to be able to rotate the magnets to

adjust the timing. It makes more sence on this motor to do it this way. I am tring to upload pictures to photobucket but it's not responding. So I will post pictures later.

I wraped three pole at a time, and all my wraps went CCW while looking

at the rotor with the positive end up. Hope that is clear, but my pictures will show it.

Originally posted by iankoglin

View Post

...therefore we don't need them...

...therefore we don't need them...

Comment